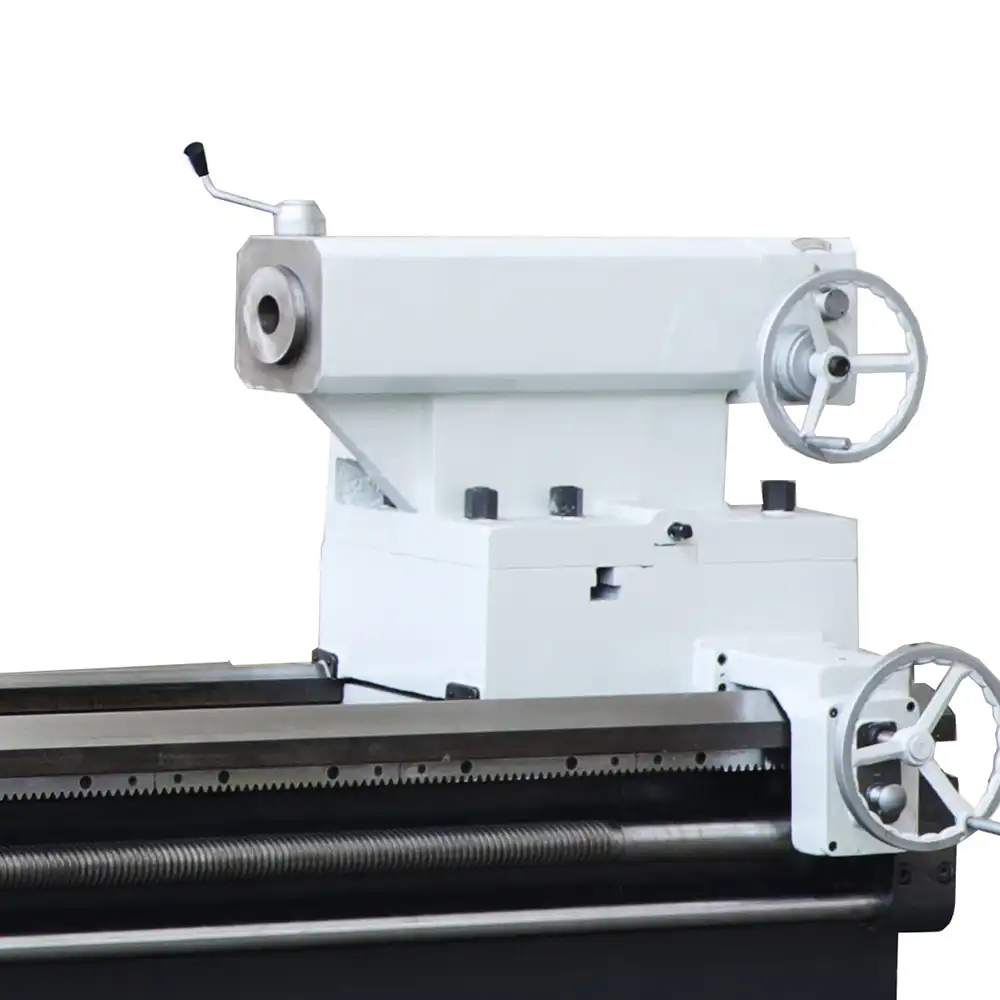

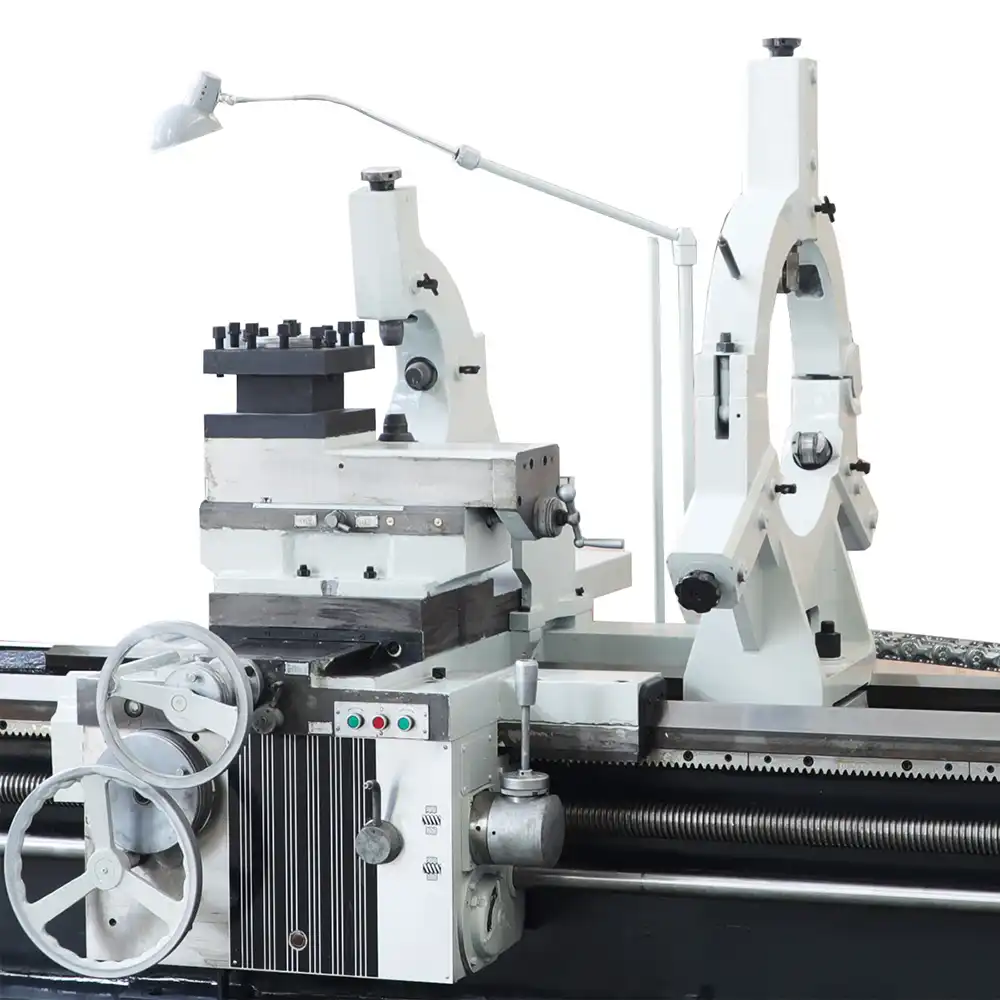

CW61100B / CW61125B / CW61140B / CW61160B Series Heavy-Duty Lathe

The CW61100B/61125B/61140B/61160B series large lathes have a load capacity of 6 tons and can turn the end faces, outer circles, inner holes, and metric threads, inch threads, module threads, diametral pitch threads of various parts. The top slide can be used independently for motorized turning of short tapers, and the top slide can also be combined with longitudinal feed for motorized turning of long tapers. It can undertake processes such as drilling, trepanning, boring, etc. The machine has high power and strong rigidity, and can use cemented carbide tools for thread cutting, to process various ferrous and non-ferrous metals.

Description

CW61100B/61125B/61140B/61160B Series Heavy-Duty Lathes

The CW61100B/61125B/61140B/61160B series heavy-duty lathes are designed to handle workpieces weighing up to 6 tons. These machines are capable of comprehensive turning operations, including facing, external and internal cylindrical turning, and cutting a wide range of threads (metric, inch, module, and diametral pitch). The top slide can be independently motorized for machining short tapers, or combined with longitudinal feed for long taper turning. Furthermore, these lathes can perform drilling, trepanning, boring, and similar processes. With their high power and robust rigidity, these machines can effectively utilize cemented carbide tools for thread cutting and machining various ferrous and non-ferrous metals.

Key Features:

High-Rigidity Integral Bed: The machine bed features a robust, integral cast structure. Its optimized internal rib layout provides exceptional rigidity. The guide rails undergo medium-frequency quenching and precision grinding. Anti-stick-slip guide plates are applied to the sliding guide surfaces, ensuring optimal dynamic characteristics such as friction damping and preventing low-speed crawling.

High-Rigidity, High-Precision Spindle: The headstock employs a symmetrical design to ensure uniform thermal expansion, preventing any displacement of the spindle center. To further minimize thermal deformation, the headstock utilizes an oil bath circulating lubrication system. The spindle’s front end is supported by a robust three-bearing structure, incorporating bi-directional angular contact ball bearings, which significantly enhances both precision and rigidity. All gears within the headstock are precision-quenched and ground, guaranteeing accurate power transmission, low noise levels, and maintaining consistent accuracy during prolonged operation.

Parameter

| ITEM | UNIT | CW61100B | CW61125B | CW61140B | CW61160B |

| CAPACITIES | |||||

| Swing over bed | mm | 1000 | 1250 | 1400 | 1640 |

| Swing over carriage | mm | 615 | 865 | 1015 | 1250 |

| Max.length of workpiece | mm | 1500 2000 3000 4000 5000 6000 8000 10000 12000 | |||

| Max.turning length | mm | 1300 1800 2800 3800 4800 5800 7800 9800 11800 | |||

| Pan of guideway | mm | 755 | |||

| SPINDLE | |||||

| Spindle nose | mm | A2-15(8×M22) | |||

| Spindle bore | mm | 130 | |||

| Taper hole of spindle | 1:20/140 | ||||

| Range of spindle speeds | r/min | forward:3.15~315 ; reverse:3.5~291 | |||

| No.of spindle speeds | forward:21; reverse:12 | ||||

| FEED | |||||

| No.of Longitudinal and cross | 56/56 | ||||

| Feed per revolution | mm | Longitudinal:0.1~12;cross:0.05~6;top slide:0.025~3 | |||

| No. and range of metric thread | 44;1~120mm | ||||

| No. and range of inch thread | 31;28~1/4 | ||||

| No. and range of module thread | 45;0.5~60mm | ||||

| No. and range of dia. thread | 38;1/2~56DP | ||||

| turret | |||||

| Distance of centerline and tool resting plane | mm | 48 | |||

| Tool post swing range | ° | ±90° | |||

| Max.travel of cross slide | mm | 520(20″) | 580 | 580 | 630 |

| Max.travel of top slide | mm | 300 | |||

| Section of tool shank | mm | 45(260×260) | |||

| Rapid travel speeds | mm/min | Longitudinal:3740;cross:1870;Little slide:935 | |||

| TAILSTOCK | |||||

| Dia. of tailstock | mm | 160(6″) | |||

| Travel of tailstock quill | mm | 300(12″) | |||

| Taper hole of tailstock quill | morse 6 | ||||

| OTHERS | |||||

| Main motor power | kw | 22 | |||

| Length | mm | 4600 5100 6100 7100 8100 9100 11100 13100 15100 | |||

| Width | mm | 2150 | |||

| Height | mm | 1700 1825 2150 | |||

| Max.weight of workpiece | kg | 6000 | |||