CK61100E/125E/140E/160E Series Large CNC Lathe

Swing over bed:1000,1250,1400,1640

Max.length of workpiece:1000 1500 2000 3000 4000 5000 6000 7000 8000 10000 12000

guideway width:755

Description

The CK61100E/125E/140E/160E series are large CNC lathes with semi-closed-loop control functionality. These machines can handle workpieces up to 6 tons and are ideal for machining a wide range of complex-shaped shafts, sleeves, and disc-like components. They can perform turning operations on inner and outer cylindrical surfaces, conical surfaces, arc surfaces, end faces, grooving, chamfering, and thread cutting, making them perfect for heavy-duty machining tasks.

Main Structural Features:

Bed Structure:

The machine bed is of an integral box-type structure made from high-standard cast iron (HT300), cast in a single step and processed with secondary aging treatment for enhanced stability.

The guideway width is 755mm, offering strong rigidity and vibration resistance.

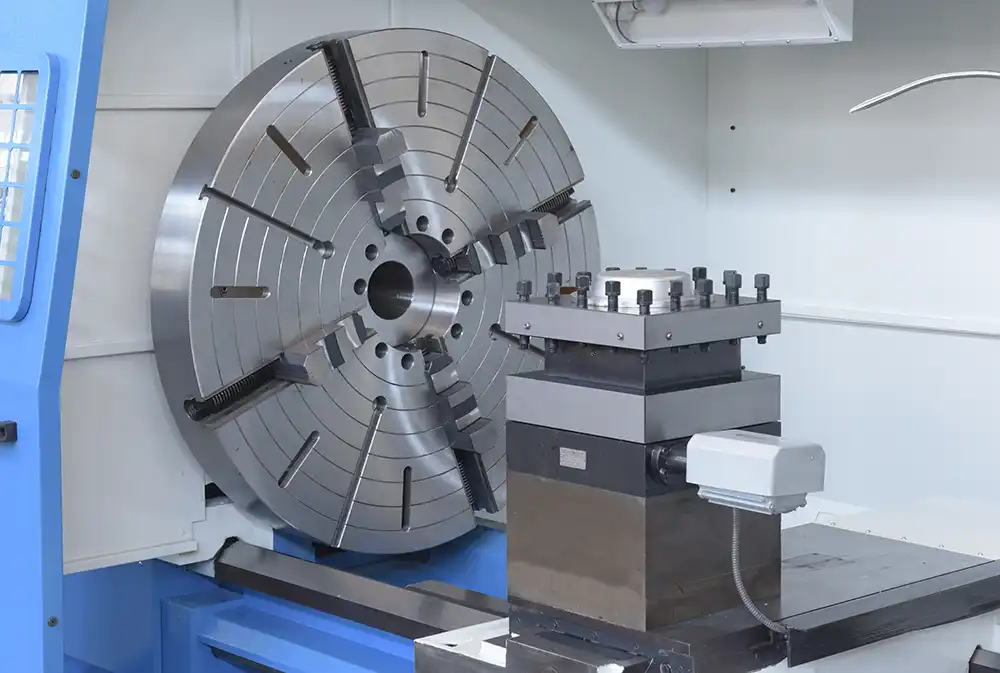

Headstock:

The headstock is designed to withstand heavy cutting operations, making it ideal for both rough and finish machining.

The gears are high-frequency quenched and precision ground, ensuring high precision, smooth operation, and low noise.

The spindle has a large diameter and is supported by precision heavy-load bearings arranged in a three-point support structure, ensuring stable rotation, high rigidity, and accuracy. The spindle also supports step-less speed variation and constant linear speed cutting.

Feeding Mechanism:

The X-axis and Z-axis use precision ground ball screw assemblies, ensuring high machining accuracy, positioning accuracy, and accuracy retention.

The automatic lubrication system provides centralized intermittent lubrication for all moving parts, ensuring smooth and reliable operation.

The longitudinal feed (Z-axis) is driven by an AC servo motor through a high-precision planetary reducer for specifications from 1000mm to 6000mm. For models exceeding 6000mm, the feed mechanism uses a rack and pinion drive system.

The machine boasts high positioning accuracy and repeated positioning accuracy, ensuring excellent consistency during operation.

Applications:

The CK61100E/125E/140E/160E series CNC lathes are perfect for a variety of heavy-duty machining applications, including:

Turning of complex components: Excellent for machining shafts, sleeves, and discs with complex geometries.

Precision cutting: Capable of machining cylindrical, conical, and arc surfaces, as well as end faces and grooving.

Threading operations: Can perform metric, imperial, modular, and tapered threads with high accuracy.

Key Industries:

Automotive: Ideal for machining heavy-duty automotive components such as axles, shafts, and transmission parts.

Aerospace: Perfect for precision turning of components used in aircraft engines and structural parts.

Energy: Suitable for turning large, complex components used in turbines and energy equipment.

Heavy Machinery Manufacturing: Used for machining large components and machinery parts with high precision.

Conclusion:

The CK61100E/125E/140E/160E series large CNC lathes are designed to handle heavy-duty, high-precision machining tasks. With their strong rigidity, high spindle accuracy, and advanced feeding systems, these lathes offer a perfect solution for industries requiring large-scale and complex machining operations. The easy programming, high adaptability, and robust design make them a reliable choice for modern manufacturing needs.

Parameter:

| Item | Unit | CK61100E | CK61125E | CK61140E | CK61160E |

| Capacities | |||||

| Swing over bed | mm | 1000 | 1250 | 1400 | 1640 |

| Swing over carriage | mm | 630 | 880 | 1030 | 1250 |

| Max.length of workpiece | mm | 1000 1500 2000 3000 4000 5000 6000 7000 8000 10000 12000 | |||

| Max.turning length | mm | 730 1300 1800 2800 3800 4800 5800 7800 9800 11800 | |||

| Pan of guideway | mm | 755 | |||

| Spindle | |||||

| Spindle nose | mm | A2-15 | |||

| Spindle bore | mm | 130 | |||

| Taper hole of spindle | 1:20/140 | ||||

| Range of spindle speeds | r/min | 3.15-315 | |||

| No.of spindle speeds | Hydraulic 4-speed automatic with infinite variability in each gear | ||||

| Center height from bed | mm | 500 | 625 | 700 | 820 |

| Chuck | mm | 1000 4-jaw | |||

| Feed | |||||

| Min.feed increment | mm | 0.001/0.001 | |||

| Rapid speeds | mm/min | 3000/5000 | |||

| Max.travel of X | mm | 570 | 630 | 700 | 630 |

| Turret | |||||

| Turret working position | Vertical 4-position(V6/V8 Optional) | ||||

| Indexing time | s | 2.6 | |||

| Indexing repeatility | mm | 0.011 | |||

| Section of tool shank | mm | 40X40 | |||

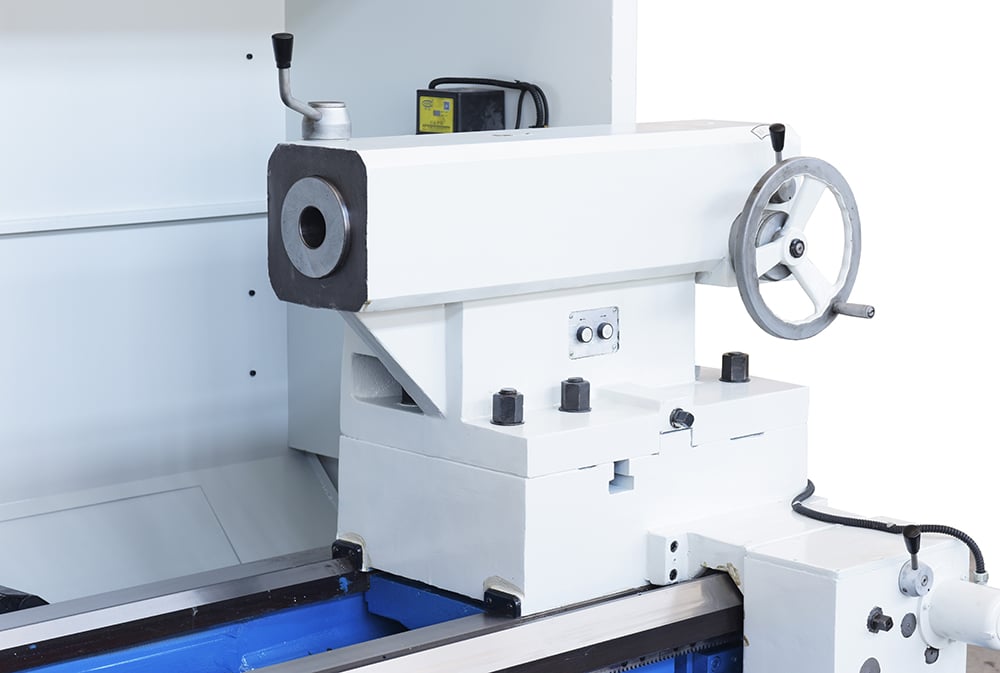

| Tailstock | |||||

| Dia. of tailstock quill | mm | 160 | |||

| Travel of tailstock quill | mm | 300 | |||

| Taperhole of tailstock | Morse6 | ||||

| Others | |||||

| Workpiece accuracy | IT7 | ||||

| Surface roughness | μm | Ra1.6 | |||

| Main power | kw | 30 | |||

| Lathe mass | kg | 9200 9800 10700 11600 12500 13500 | |||

| Length | mm | 4800 5300 6300 7300 8300 9300 | |||

| Width | mm | 2530/2300/ ,2780/2600 | |||

| Height | mm | 2300 | 2600 | 2600 | 2600 |

| CNC System | FANUC 0i-TF/SIEMENS 828D/GSK980TDC | ||||