Understanding Machine Tools: Definition, History, Components, and Classification

Introduction

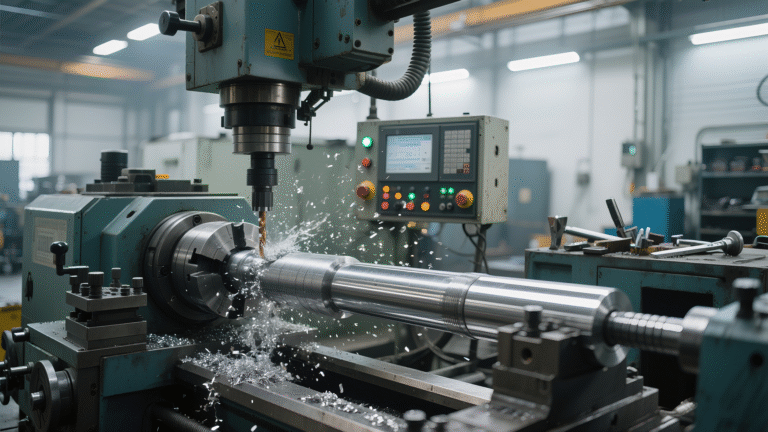

Machine tools are essential devices used for processing workpieces in the manufacturing of mechanical components. They serve as power-driven devices that shape, cut, and connect materials, primarily focusing on metal workpieces.

Concept and Definition

Machine tools are defined as power-driven devices that process solid materials through physical or chemical methods. Typically, they are used for machining metal workpieces. The processing methods include cutting and grinding, which shape the workpieces to the required dimensions and surface precision. Based on their functions, machine tools can be categorized into three types: cutting machines, forming machines, and advanced technology machines. Metalworking machine tools are specifically designed for precision cutting of metals to produce components for other machines, requiring a robust structure to ensure rigidity.

Historical Development

The origins of machine tools can be traced back to ancient tools used for drilling holes in stone. A significant advancement occurred in 1712 when Thomas Newcomen invented the atmospheric piston steam engine. In 1765, James Watt proposed a new steam engine design that separated the condenser from the cylinder, allowing the cylinder temperature to be maintained at the steam injection temperature, thus improving the efficiency of Newcomen’s steam engine. However, the technology of machine tools at that time could only achieve a tolerance of about two centimeters, which posed challenges in assembling the large piston and cylinder of the new steam engine. In 1775, John Wilkinson developed the boring machine, which improved machining tolerances to several millimeters, successfully addressing a critical technical challenge for Watt’s steam engine. Consequently, in 1776, Watt manufactured the first batch of more efficient steam engines for practical use. Today, machine tools also encompass 3D printers.

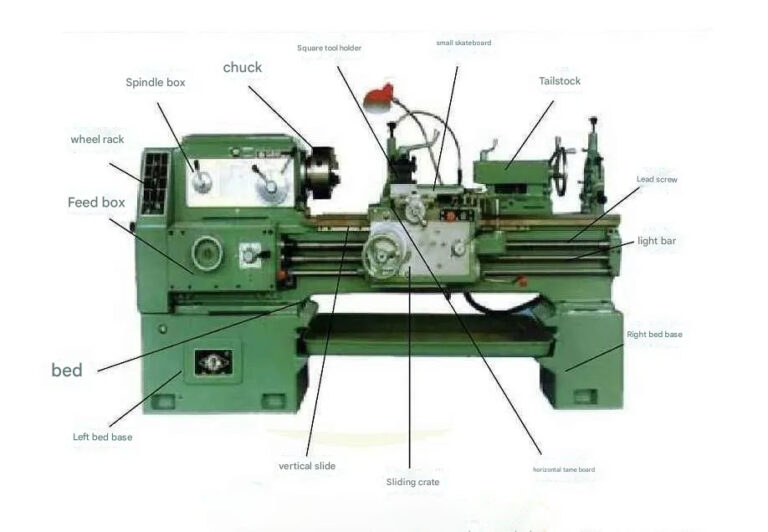

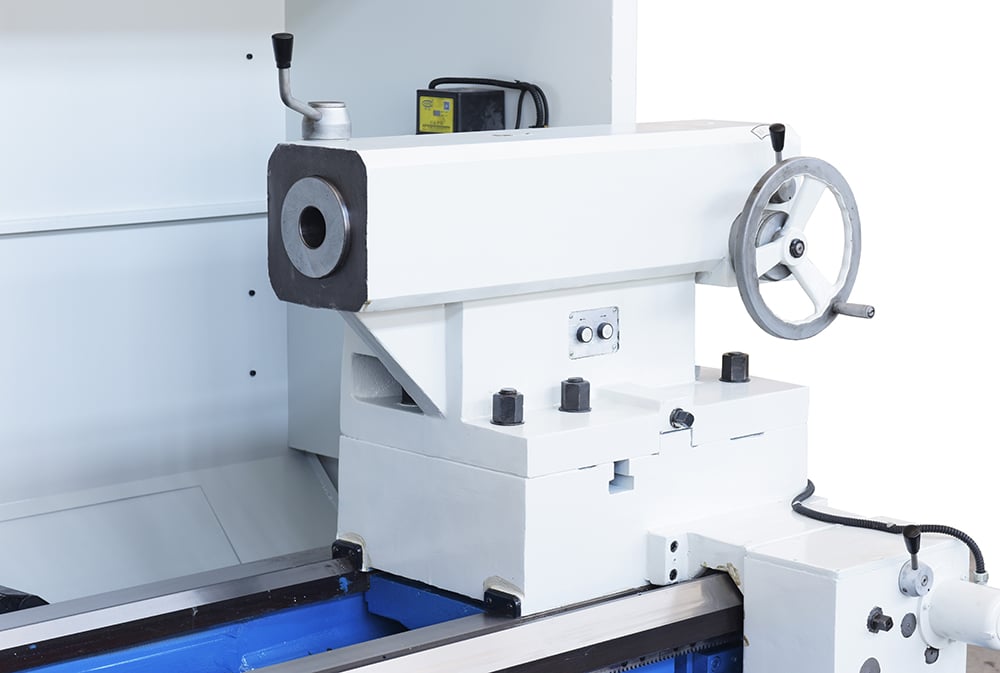

Components of Machine Tools

In machine tools, the metal being processed is referred to as the “workpiece,” while the tool used for cutting the workpiece is called the “cutter.” Machine tools provide the power to create relative motion between the workpiece and the cutter, precisely controlling this motion to remove unwanted material from the workpiece. Some machines, like lathes, rotate the workpiece while feeding the cutter, whereas others, like boring machines, rotate the cutter while moving the workpiece.

The basic components of machine tools include:

- Headstock: Provides the drive and feed for the cutter or rotates the workpiece, containing the spindle and gear system.

- Column: Offers vertical support, with some machines allowing vertical movement of the headstock.

- Table: Supports and secures the workpiece during machining, with some machines providing feeding capabilities.

- Saddle, Bed, and Guideways: Support other components and sometimes provide degrees of freedom for feeding.

Power Sources

The power for machine tools is typically supplied by electric motors, which can be classified into direct current (DC) and alternating current (AC) motors. Traditionally, DC motors have advantages such as high power output, smooth acceleration and deceleration, and lower operating temperatures. However, they have drawbacks, including wear-prone components like brushes and potential fire hazards from sparks during rectification. AC motors, on the other hand, do not require brushes and have seen advancements in power and responsiveness in recent years. The most advanced technology currently involves linear motors directly driving machine tool axes through transmission mechanisms like ball screws or gear racks.

Classification of Machine Tools

Machine tools can be classified based on their processing methods into categories such as milling machines, lathes, grinding machines, and drilling machines. They can also be categorized by their construction into types like bench-type, floor-type, gantry-type, and multi-spindle machines. Furthermore, based on automation levels, they can be divided into traditional metal cutting machines, numerical control (NC) machines, and computer numerical control (CNC) machines.

CNC Machine Tools

CNC machine tools have become vital equipment in the parts processing industry. Compared to traditional machine tools, CNC machines are better suited for the production of precision components.

Advantages of CNC Machines:

- High precision and quality.

- Easy data storage and modification, allowing programs to be reused across different machines without redesigning.

- Higher automation levels with features like automatic tool changing and feeding.

- Adaptive control to maintain optimal production conditions.

- Longer tool life.

- Increased operational time, enhancing machine utilization (can operate unattended).

- High efficiency, quality, and yield, especially evident in complex and intricate finished shapes.

- Reduced need for fixtures and jigs, lowering upfront costs and preparation time.

- Versatility in processing, reducing unit costs in low-volume, high-variety production.

- Decreased labor costs, as one operator can manage multiple machines.

- Easier control of processing time and unit costs, facilitating effective production planning and reducing idle materials.

- Simplified operation, reducing reliance on highly skilled operators once the program is designed.

- Elimination of operator errors, improving yield rates.

Disadvantages of CNC Machines:

- High initial purchase cost.

- Programmers must possess knowledge of machining and operations.

- Complex equipment requires high maintenance and upkeep costs.

- Dependence on skilled programmers and mechanical maintenance personnel, who require more training than typical technicians.

Operation of Machine Tools

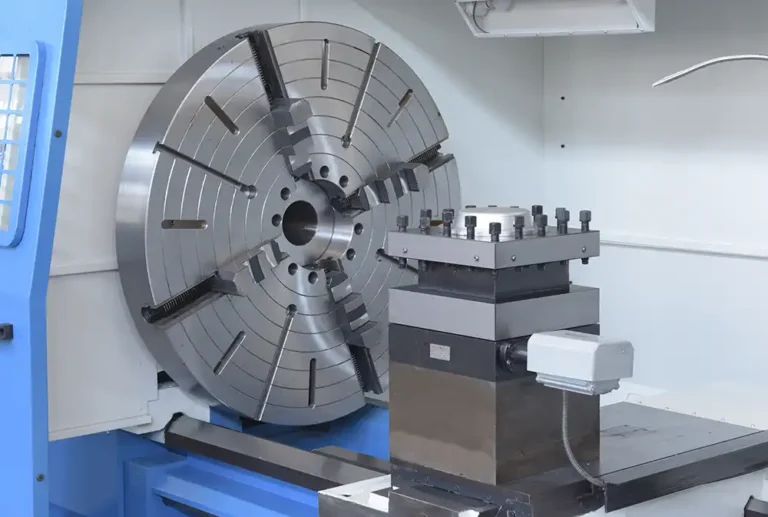

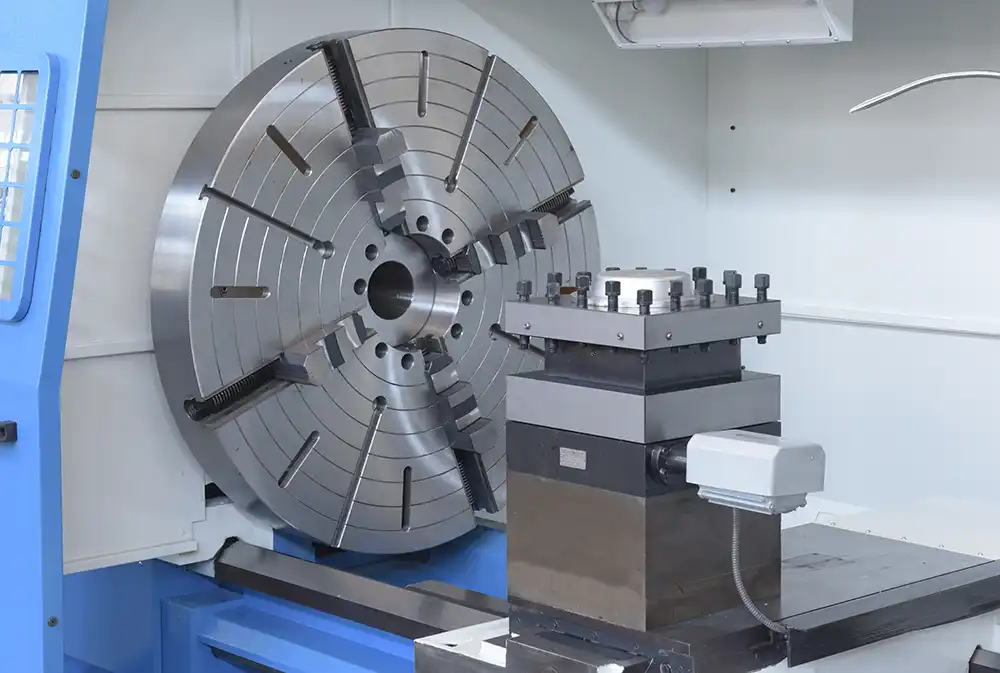

Workpieces can be held using various methods, including:

- Two-Pin Support: The workpiece is held by a pin in the headstock and another in the tailstock, suitable for long workpieces under rotation.

- Centering Shaft: A shaft extends from the headstock through an existing hole in the cylindrical workpiece.

- Faceplate: The workpiece is secured to a faceplate using fixtures, ideal for flat or irregularly shaped components.

- Chucks: Clamping devices that grip the workpiece.

In addition to operator safety training, machine tools are equipped with various safety features, such as protective barriers to prevent foreign objects from entering, photoelectric sensors for emergency stops, and dual-button control systems to enhance safety.

Conclusion

Machine tools play a crucial role in modern manufacturing, enabling precision and efficiency in the production of mechanical components. Understanding their components, classifications, and operational principles is essential for anyone involved in the manufacturing industry.