Machine Tools: Foundations of Modern Manufacturing

Machine tools are foundational to modern industry and engineering. These complex and precise machines are designed to handle or machine metal and other rigid materials through processes such as cutting, grinding, boring, shearing, or other forms of controlled deformation. In essence, machine tools shape the materials that form the backbone of modern infrastructure and technology.

Definition and Core Principles

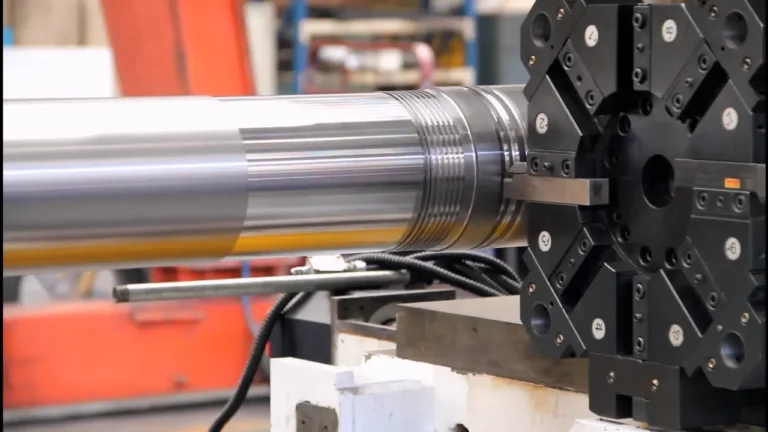

A machine tool is a power-driven machine that shapes or forms materials, usually metal, by removing excess material or deforming the workpiece in a controlled manner. Unlike hand tools, machine tools employ mechanisms that constrain both the workpiece and the cutting tool, guiding them in specific paths known as toolpaths. This capability distinguishes them from earlier, freehand techniques and ensures consistency, precision, and repeatability in manufacturing.

While the precise definition varies, machine tools generally refer to machines that perform metal cutting or forming operations using a tool. Not all machines in a factory are classified as machine tools; the term is specifically reserved for those that alter the shape or size of materials through cutting or mechanical deformation.

Historical Development

The origins of machine tools can be traced back to ancient technologies such as bow drills, lathes, and potter’s wheels. However, true machine tools, characterized by mechanically guided toolpaths, only emerged during the late Middle Ages and the Renaissance.

A major leap occurred in 1774 when John Wilkinson invented a boring machine that allowed James Watt to finally produce accurately bored cylinders for steam engines. This invention marked a turning point in precision manufacturing.

Throughout the 18th and 19th centuries, engineers like Henry Maudslay, Joseph Whitworth, and James Nasmyth refined techniques such as screw-cutting and surface gauging. These developments enabled the production of interchangeable parts, which laid the groundwork for mass production.

During the Industrial Revolution, the demand for precision-machined metal components for textile machinery, steam engines, firearms, and later, automobiles and aircraft, drove rapid advances in machine tool technology.

Key Innovations and Types

Early machine tools included:

Slide rest lathes

Screw-cutting lathes

Turret lathes

Milling machines

Shapers

Metal planers

These machines introduced a new level of accuracy and efficiency. For example, standardization of screw threads was only possible once screw-cutting lathes could produce threads with high precision.

By the 20th century, machine tools had become vital to industries ranging from automotive to aerospace. During World War II, U.S. production of machine tools tripled, playing a crucial role in the Allied victory.

Drive Power Sources

Initially powered by human or animal effort, early machine tools used treadles, hand cranks, or water wheels. The Industrial Revolution brought about widespread use of steam power, followed by hydraulic, pneumatic, and ultimately electric power as the dominant source.

Today, almost all machine tools are electrically powered, offering greater control and efficiency. Hydraulic and pneumatic systems are sometimes used for specific applications requiring force over speed or precision.

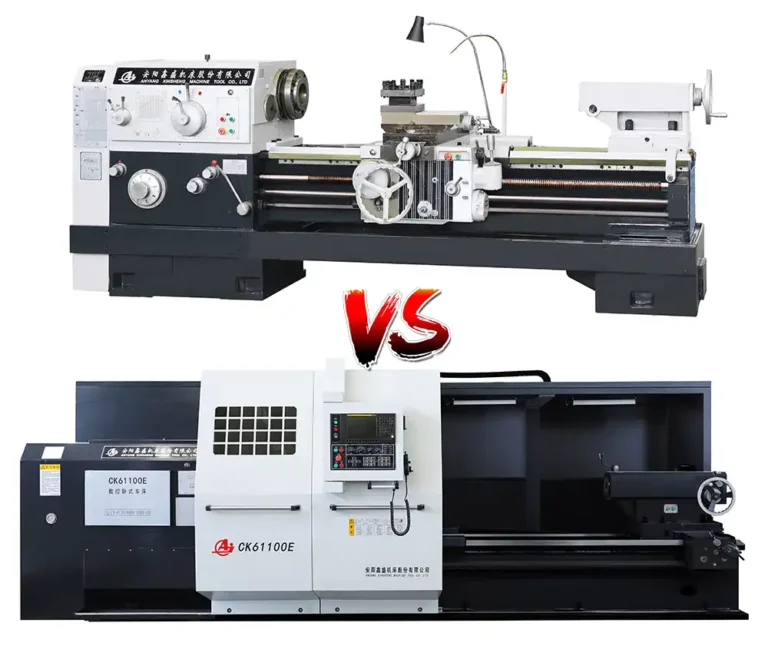

Automatic Control and CNC

Early machine tools relied on manual control, often using levers, gears, and flywheels. The development of numerical control (NC) in the 1940s and computer numerical control (CNC) in the 1960s revolutionized the industry.

CNC machines use computer programs to automate and precisely control movements, allowing for:

Repeatability and consistency

Reduced human error

Complex geometries

Multi-axis motion

Advanced machining centers can change tools automatically and perform several operations—drilling, milling, turning—on a single setup, dramatically increasing productivity and reducing labor.

Contemporary Machine Tool Technologies

The evolution of machining has extended beyond conventional cutting and grinding to include:

Electrical discharge machining (EDM)

Laser machining

Ultrasonic machining

Water jet and plasma cutting

Moreover, the line between subtractive and additive manufacturing is blurring. Modern hybrid machines can perform both traditional machining and additive manufacturing (e.g., 3D printing) within a single system, pushing the boundaries of manufacturing flexibility.

Economic and Industrial Significance

Machine tools have enabled industrialized nations to develop complex infrastructure and consumer products. Today, major producers of machine tools include:

China

Japan

Germany

South Korea

Italy

United States

Switzerland

Taiwan

The global machine tool industry continues to innovate through public and private R&D, supporting advancements in robotics, automation, and smart manufacturing systems.

Conclusion

Machine tools are indispensable in the fabrication of virtually every engineered product. From their origins in the age of hand craftsmanship to their current role in computer-controlled, high-precision manufacturing, they have shaped the modern world. As technology continues to evolve, machine tools will remain at the core of industrial progress, adapting to new materials, methods, and markets.