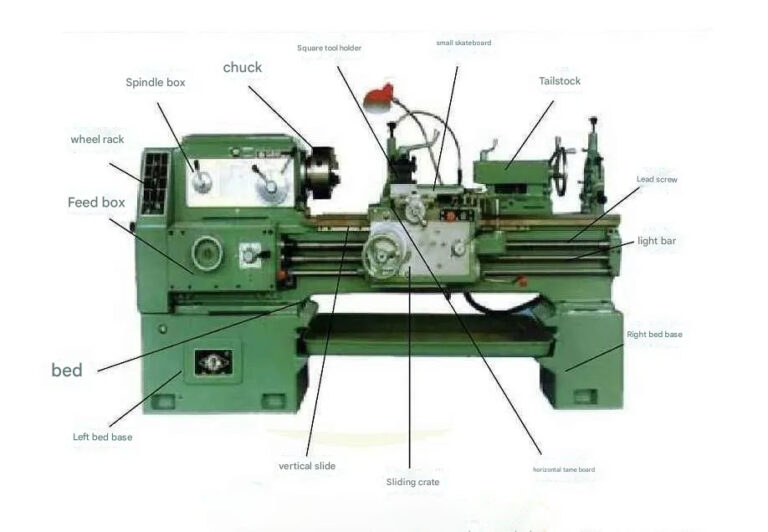

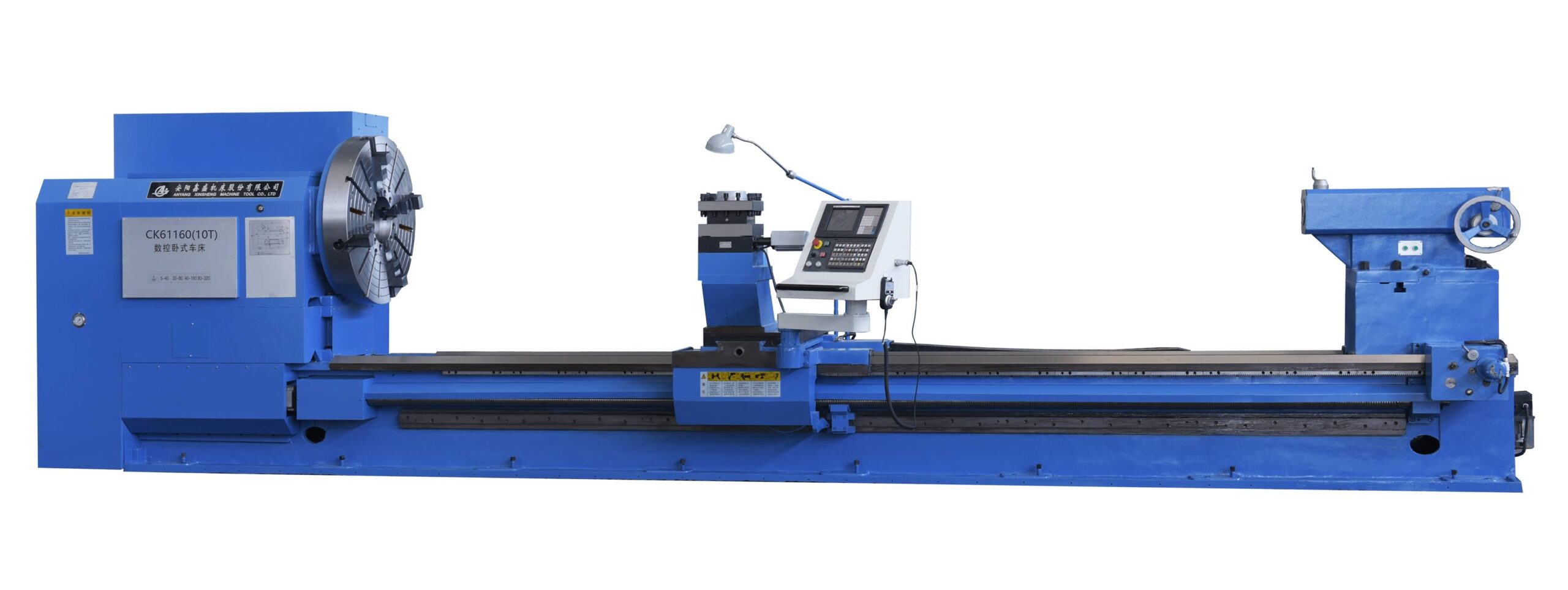

Lathe maintenance procedures

I. Daily Maintenance Content and Requirements

Before Shift:

Wipe off dust from exposed guideways and sliding surfaces of the machine tool.

Lubricate all parts as specified; oil quantity must meet requirements.

Check positions of all handles.

Perform a no-load trial run.

After Shift:

Clean away all iron chips.

Wipe clean all parts of the machine tool.

Return all components to their designated positions.

II. Primary and Secondary Maintenance Content and Requirements

1. Appearance

Primary Maintenance:

Clean the machine’s exterior and hidden corners; remove and wash all covers, ensuring both inside and outside are clean, free of rust and yellow stains; paint should be visible and metal surfaces should be bright.

Clean the lead screw, feed rod, and rack; must be free of grease and dirt.

Inspect and replenish screws, knobs, and handles.

Secondary Maintenance:

Same as above.

Inspect guideways, smooth out burrs, and repair worn or damaged areas as necessary.

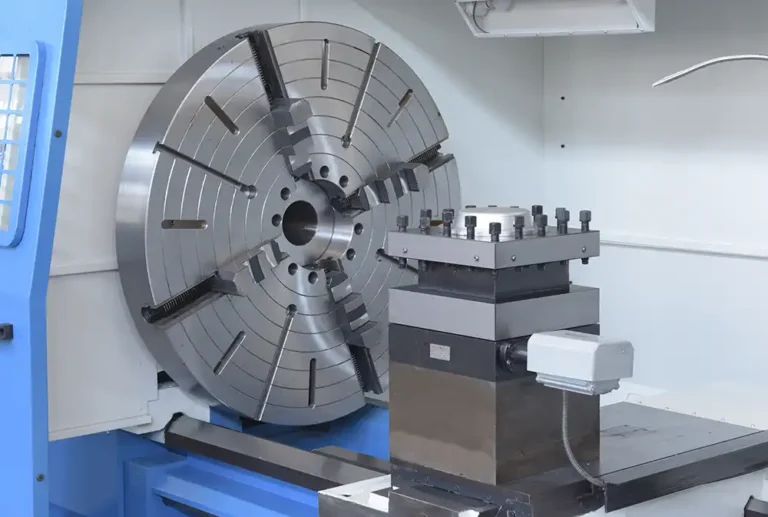

2. Tool Rest, Crossbeam, Column, Guideway, and Worktable

Primary Maintenance:

Clean guideways, oil passages, and felt pads; oil passages must be unblocked, felt pads effective, and new oil added.

Check and adjust gib clearances.

Secondary Maintenance:

Same as above.

Remove the tool rest, clean guideways, unblock oil passages, smooth burrs, check and replace worn parts as needed, and repair worn or damaged areas.

Disassemble and clean the worktable; check and replace worn parts as needed.

3. Transmission Box

Primary Maintenance:

Inspect oil quality to ensure it remains good; oil cups must be complete; oil quantity must meet requirements; oil sight glass must be clear.

Secondary Maintenance:

Same as above.

Inspect all gearbox transmission mechanisms and replace worn parts as necessary.

Inspect and adjust speed change interlocks and positioning devices to ensure correct and reliable operation.

4. Lubrication & Hydraulic System

Primary Maintenance:

Ensure lubrication in all parts, with unobstructed oil passages, clean oil pipes and felt pads, and firmly fixed pipelines; no leakage allowed.

Check oil pressure gauge and unloading mechanism.

Secondary Maintenance:

Same as above.

Inspect oil pump and pipelines; pipelines must be neatly arranged and oil passages unobstructed; adjust all valves to ensure normal oil pressure.

5. Electrical System

Primary Maintenance:

Clean dust from the motor and inside/outside of the electrical cabinet.

Secondary Maintenance:

Same as above.

Overhaul electrical components; disassemble and clean the motor, replace grease if necessary.

Overhaul solenoid valves.

6. Accuracy

Secondary Maintenance:

Inspect and adjust to ensure that the main geometric accuracy meets factory standards or production process requirements.