Description

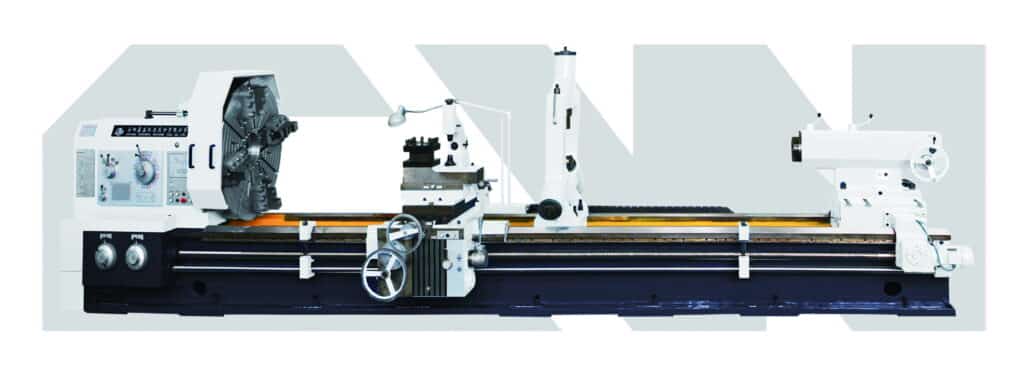

The CW61125/61140/61160 (10T) series is a conventional heavy-duty lathe designed to support a load capacity of up to 10 tons. With a bed guide width of 970mm, these machines are primarily used for machining large, heavy workpieces. They can handle turning various components, including end faces, outer diameters, inner bores, and threads such as metric threads, imperial threads, module threads, and tapered threads. Additionally, the machine can perform operations like drilling, reaming, and boring. It is also capable of turning tapered surfaces with the upper tool post independently or in combination with longitudinal feed for machining long tapers.

This series of heavy-duty lathes features high power and rigidity, making it suitable for use with carbide tools for threading operations and processing a range of ferrous and non-ferrous metals.

Key Features:

- High Rigidity Integrated Bed:

The lathe features an integrated cast structure bed with a well-designed internal rib layout. The guideways are treated with medium-frequency quenching and grinding processes. Anti-crawling guide plates are applied to the sliding guide surfaces, optimizing friction damping and dynamic properties to prevent low-speed crawling. - High Rigidity, High Precision Spindle:

The spindle is equipped with high-quality bearings from reputable domestic manufacturers. The spindle box adopts a symmetric structure to ensure uniform thermal deformation, preventing displacement of the spindle center. To reduce thermal deformation, the headstock is lubricated with oil bath circulation. The spindle end is supported by a three-support structure with angular contact ball bearings, enhancing both precision and rigidity. The gears inside the spindle box are subjected to quenching and grinding processes to ensure precise transmission and low noise. The spindle operates with low vibration, minimal thermal deformation, and maintains high precision over long periods of operation.

Application:

- Heavy Workpieces: The lathe is ideal for turning large and heavy parts, including those used in the automotive, aerospace, and machinery manufacturing industries.

- Precision Threading and Bore Machining: Suitable for both large-diameter components and precision threading, the machine can produce various types of threads with high accuracy.

- Multi-Purpose Machining: Can handle multiple processes like drilling, boring, reaming, and threading, making it a versatile choice for a wide range of machining tasks.

With its robust design, the CW61125/61140/61160 series provides high performance and stability, ensuring precision and durability in demanding machining applications.

Parameter:

| ITEM | UNIT | CW61125 | CW61140 | CW61160 |

| CAPACITIES | ||||

| Swing over bed | mm | 1250 | 1400 | 1600 |

| Swing over carriage | mm | 865 | 1010 | 1210 |

| Max.length of workpiece | mm | 3000 4000 5000 6000 8000 10000 12000 | ||

| Max.turning length | mm | 2800 3800 4800 5800 7800 9800 11800 | ||

| Pan of guideway | mm | 970 | ||

| Max.cutting force | N | 45000 | ||

| Max.weight of workpiece | kg | 10000 | ||

| SPINDLE | ||||

| Dia.of spindle hole | mm | 130 | ||

| Taper hole of spindle | Metric140 | |||

| Range of spindle speeds | r/min | forward:3.15~315; reverse:3.5~291 | ||

| No.of spindle speeds | forward:21; reverse:12 | |||

| FEED | ||||

| Longitudinal and cross | 56 | |||

| Range of feed motion | mm | longitudinal:0.1~12;cross:0.05~6; top siide:0.025~3 | ||

| No. and range of metric thread | 44;1~120 | |||

| No. and range of inch thread | 31;28~1/4 | |||

| No. and range of module thread | 45;0.5~60 | |||

| No. and range of dia. thread | 38;1/2~56DP | |||

| TURRET | ||||

| Max.travel of cross slide | mm | 650 | ||

| Max.travel of top slide | mm | 300 | ||

| Section of tool shank | mm | 45(260×260) | ||

| Tool post swing range | ° | ±90° | ||

| Rapid of tool post | mm/min | Longitudinal:3740;cross:1870;top slide:935 | ||

| Max.travel of tool post | mm | 2900 3900 4900 5900 7900 9900 11900 | ||

| TAILSTOCK | ||||

| Dia. of tailstock | mm | 220 | ||

| Travel of tailstock quill | mm | 300 | ||

| Taper hole of tailstock quill | morse 6 | |||

| OTHERS | ||||

| Main motor power | kw | 22 | ||

| Length | mm | 6020 7020 8020 9020 11020 13020 15020 | ||

| Width | mm | 1995 | ||

| Height | mm | 2175 2325 2525 | ||