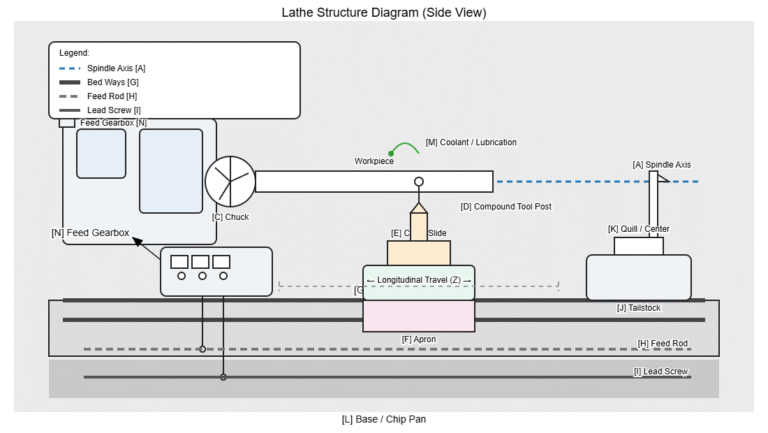

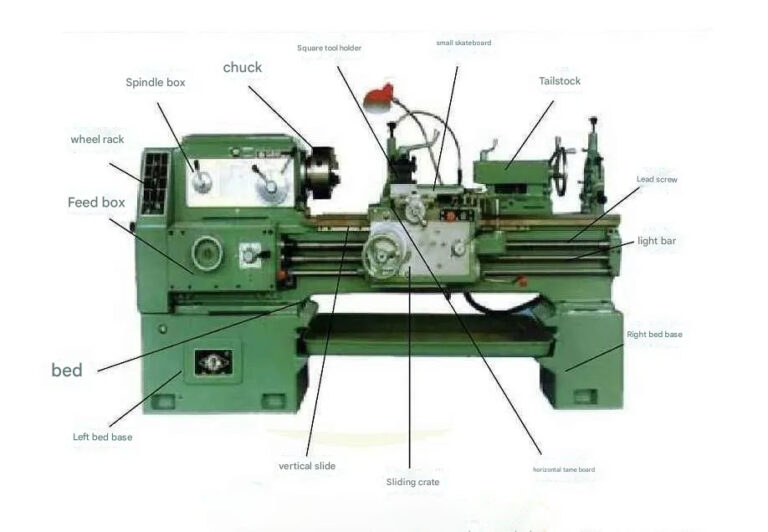

Detailed Composition of a Conventional Lathe

A conventional lathe, also known as an engine lathe, is one of the most widely used machine tools in manufacturing. It works by rotating a workpiece while a cutting tool is applied to it. Below is a detailed description of the main components of a conventional lathe with English and Chinese translations. ID Name Function…