Regarding the Imitation of Our Company Name, Products, and False Manufacturing Claims

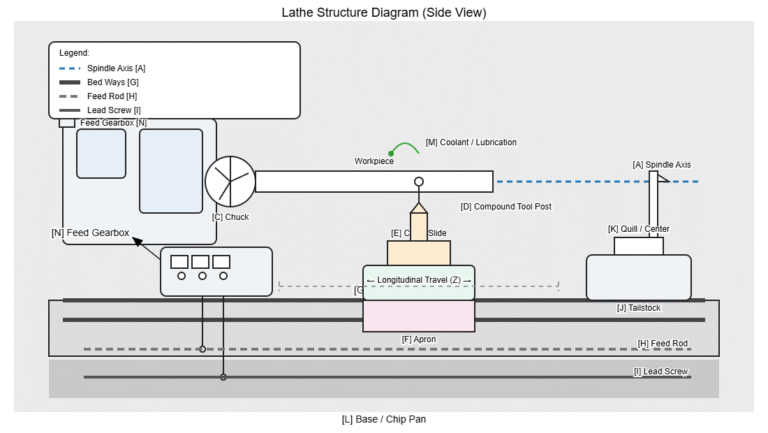

Recently, Anyang Xinsheng Machine Tool Co., Ltd has identified that Anyang Xinheng Machine Tool Co. Ltd / Anyang Xinheng Machine Tool Co., Ltd has been deliberately imitating our company name, products, website content, and marketing materials, and promoting them globally through multiple websites and social media platforms.These actions have seriously misled customers and infringed upon…