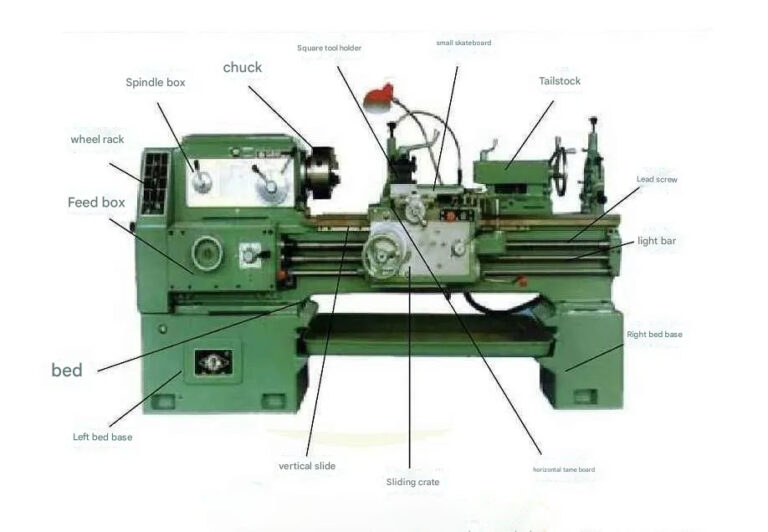

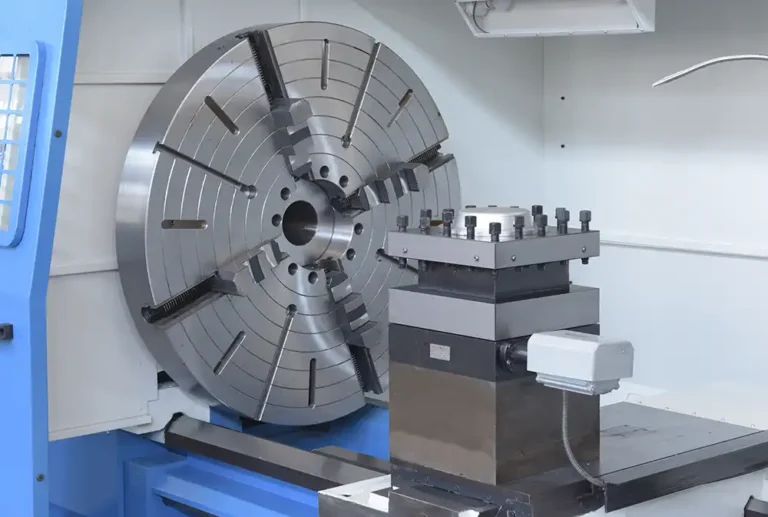

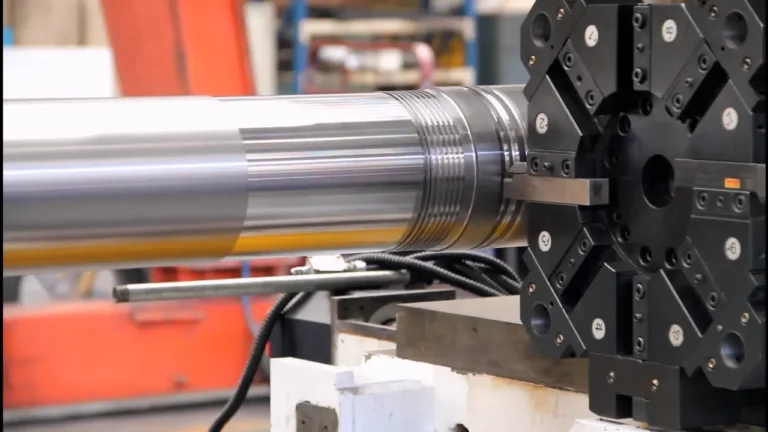

What does the performance of a lathe refer to?

The performance of a lathe includes: machining performance, operational performance, and parameter performance. Machining performance refers to cutting efficiency (whether high-speed cutting is possible to shorten machining time and improve cutting efficiency) and the range of parts that can be machined (whether it can carry out various turning operations, including turning metric threads, inch threads,…