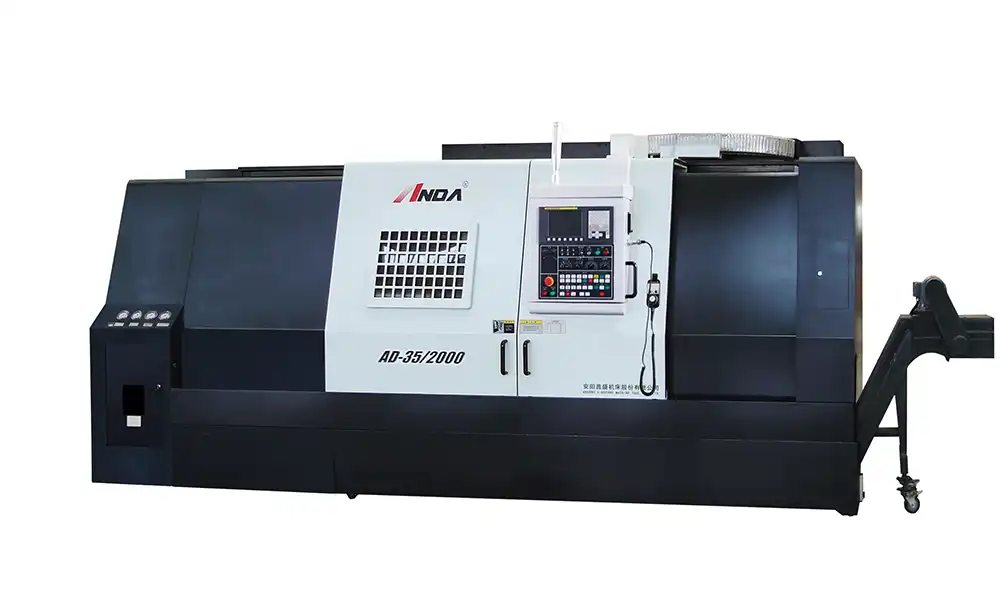

AD Series Full-Function CNC Lathe

The Conventional Heavy Duty Horizontal Lathe is a robust and versatile machine tool designed for turning large, heavy workpieces. This type of lathe is commonly used in industries such as automotive, aerospace, energy, and heavy machinery manufacturing. It is specifically built to handle high loads and deliver precision machining for a variety of complex operations, including turning, drilling, boring, threading, and more.

Description

Conventional Heavy Duty Horizontal Lathe Introduction

The Conventional Heavy Duty Horizontal Lathe is a robust and versatile machine tool designed for turning large, heavy workpieces. This type of lathe is commonly used in industries such as automotive, aerospace, energy, and heavy machinery manufacturing. It is specifically built to handle high loads and deliver precision machining for a variety of complex operations, including turning, drilling, boring, threading, and more.

These lathes are ideal for producing large-diameter components, such as shafts, gears, and engine parts, and can efficiently process both ferrous and non-ferrous metals. The horizontal design of the bed and the powerful motor systems allow for stable and accurate performance during heavy-duty machining tasks.

Key Features:

- Heavy-Duty Construction:

Built with a solid cast-iron bed and reinforced with internal ribs, these machines provide exceptional rigidity and stability during machining, reducing vibrations and ensuring high-precision results even under heavy workloads. - High Load Capacity:

Designed to handle workpieces with a high weight capacity, often up to 10 tons or more, making them ideal for large-scale components and critical manufacturing processes. - Precision and Versatility:

Capable of performing various operations such as turning, threading (metric, imperial, and modular threads), boring, drilling, and reaming. The machines are also equipped with advanced features like taper turning capabilities, both manually and automatically. - High Precision Spindle:

The machine’s spindle is designed for high precision, often supported by high-quality bearings to minimize thermal deformation and maintain accuracy. The spindle is lubricated using oil bath circulation, enhancing long-term operational stability. - Powerful Drive System:

These lathes are powered by high-torque motors that provide the necessary strength for cutting through tough materials and handling large workpieces without compromising on performance. - User-Friendly Controls:

The control systems are designed to be intuitive, allowing operators to quickly learn and operate the machine, increasing efficiency in the production process. - Durable Guideways:

The bed guideways are typically heat-treated and precision-ground to ensure long-term wear resistance and optimal dynamic properties, improving the overall lifespan of the machine.

Applications:

- Automotive Industry: Machining large components such as crankshafts, flywheels, and transmission parts.

- Aerospace Industry: Precision turning of aircraft components like engine housings and structural parts.

- Energy Sector: Machining parts for turbines, compressors, and other heavy equipment used in power generation.

- Heavy Machinery Manufacturing: Producing large mechanical components like shafts, gears, and housings.

Advantages:

- Heavy Load Handling: Capable of machining large and heavy workpieces with ease.

- Versatile Machining: Suitable for a wide range of operations and materials.

- High Precision and Stability: Ensures high-quality surface finishes and dimensional accuracy, even in demanding conditions.

- Durable and Reliable: Built for longevity and consistent performance in tough industrial environments.

The Conventional Heavy Duty Horizontal Lathe offers outstanding performance, flexibility, and durability, making it an essential tool for industries requiring high-capacity and high-precision machining.

Parameter:

| Item | Unit | AD10 | AD15B | AD25 | AD35 | AD35B | AD45 |

| CAPACITIES | |||||||

| Swing over bed | mm | 450 | 500 | 600 | 700 | 700 | 850 |

| Max. dia. cutting | mm | 300/260 | 320/320 | 420/420 | 550/500 | 550/500 | 800/650 |

| Max.workpiece length | mm | 600/1100 | 600/1100 | 625/1000/1500/2000/3000 | 890/1640/2000/3000 | 1640 | 1500/2000/3000 |

| Max. turning length | mm | 450/950 | 450/950 | 530/905/1405/1905/2905 | 780/1530/1890/2890 | 1530 | 1420/1920/2920 |

| FEED | |||||||

| x-axis travel | mm | 170 | 190 | 230 | 305 | 335 | 450 |

| z-axis travel | mm | 460/960 | 460/960 | 590/965/1465/1965/2965 | 865/1605/1965/2965 | 1605 | 1450/1950/2950 |

| Rapid travel of x | 18 | 18 | 12 | 12 | 12 | 12 | |

| Rapid travel of z | 20 | 20 | 15 | 15 | 12 | 15 | |

| X/Z feed speed | 1260 | 1260 | 1260 | 1260 | 1260 | 1260 | |

| SPINDLE | |||||||

| Spindle speed | rpm | 50-4500 | 45-4000 | 35~3500 | 25~2500 | 25~1000 | 10~2000 |

| Spindle power | kw | 7.5 | 11 | 18.5/15 | 30/22 | 22 | 100 |

| Spindle nose | A2-5 | A2-6 | A2-8 | A2-8 | A2-11 | A2-11 | |

| Spindle bore(Dia.) | mm | 50 | 62 | 87 | 92 | 92 | 131 |

| Size of chuck | inch | 6 | 8 | 10 | 12 | 12 | 15/18 |

| Front bearing dia. | mm | 80 | 100 | 130 | 160 | 160 | 200/240 |

| TOOL POST | |||||||

| NO. of stations | 8 | 8 | 12 | 12 | 12 | 12 | |

| Indexing time | s | 0.58 | 0.58 | 0.3 | 1 | 1 | 1 |

| Size of turret | mm | 20X20 | 25X25 | 25X25 | 25X25 | 32X32 | 32X32 |

| Dia. of bar shank | mm | 32 | 40 | 40 | 50 | 60 | 60 |

| TAILSTOCK | |||||||

| Max. travel | mm | 360 | 360/860 | 490/865/1365/1865/2865 | 706/1456/1816/2816 | 1456 | 1400/1900/2900 |

| Quill Dia | mm | 80 | 80 | 85 | 110 | 110 | 140 |

| Quill taper hole | MT-4 | MT-4 | MT-5 | MT-5 | MT-5 | MT-6 | |

| Quill travel | mm | 100 | 100 | 80 | 100 | 100 | 130 |

| OTHERS | |||||||

| Main power | kw | 20 | 25 | 30 | 46 | 50 | 130 |

| Weight | t | 3.5/4.5 | 3.6/4.8 | 5/5.5/6.5/7.5/8.5 | 8/10.1/11.5/15.5 | 10 | 15/16/18 |

| Length | mm | 2575/3470 | 2575/3470 | 3000/3380/4550/4960/6160 | 3620/4725/5825/7000 | 5614 | 6360/6860/7860 |

| Width | mm | 1485 | 1485 | 1545 | 1820 | 2031 | 2350 |

| Hight | mm | 1700 | 1700 | 1950 | 2130 | 2147 | 2600 |

| Accuracy/roughness | μm | IT6/Ra0.8 | IT6/Ra0.8 | IT6/Ra0.8 | IT6/Ra0.8 | IT6/Ra0.8 | IT6/Ra1.6 |

| CNC system | FANUC 0i-TF (Other systems can be optionally selected as needed) | ||||||