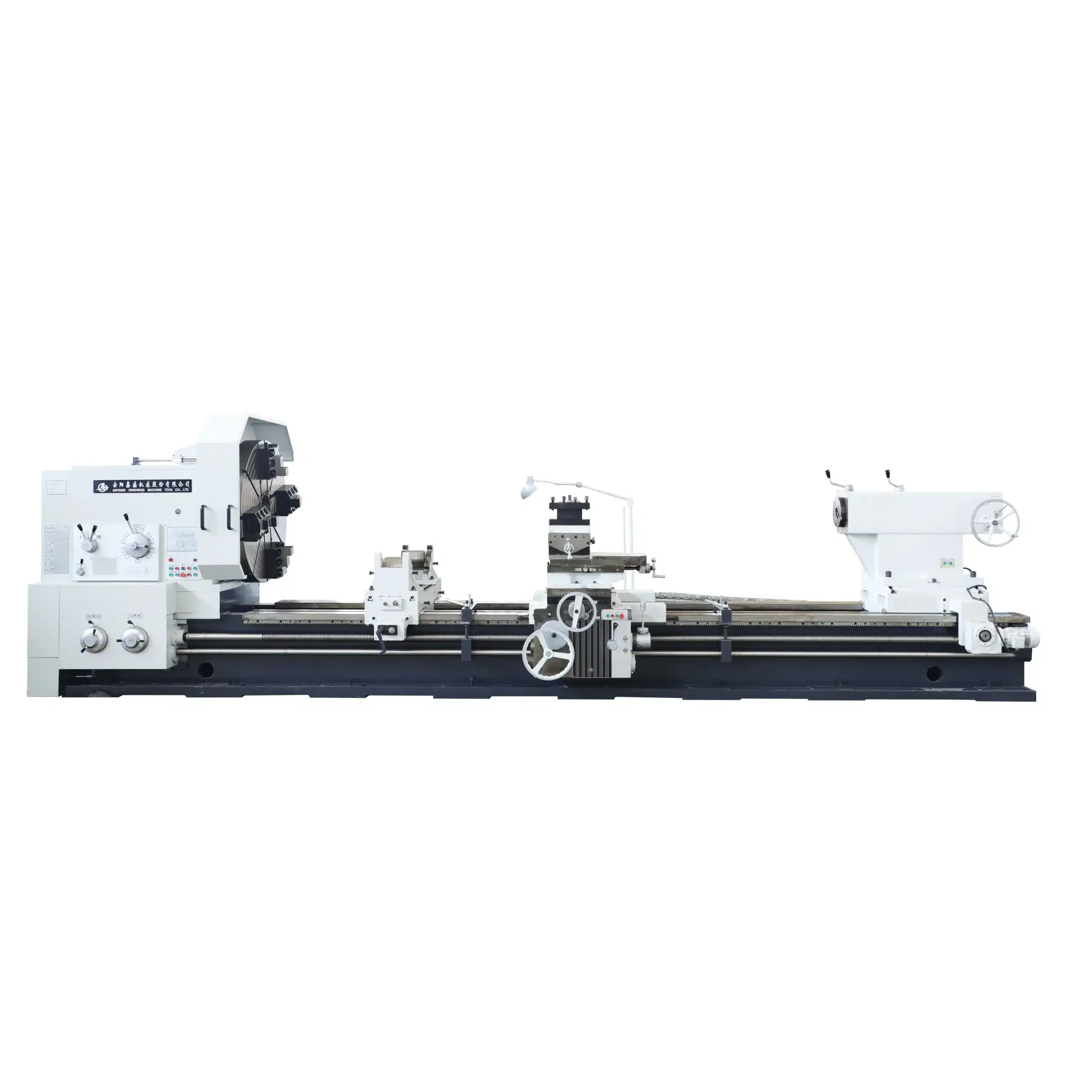

C61125 61160 61180 61200(16ton) Heavy Duty Horizontal Conventional Lathe

The C61125/61160/61180/61200 series heavy-duty machine tools are designed to handle workpieces with a maximum load capacity of up to 16 tons.

Description

C61125/61160/61180/61200 Heavy-Duty Machine Tool Introduction

The C61125/61160/61180/61200 series heavy-duty machine tools are designed to handle workpieces with a maximum load capacity of up to 16 tons. These machines feature a rectangular guide rail structure that ensures excellent stability and rigidity. The bed guideways are processed using medium-frequency quenching and grinding, enhancing durability and precision. The spindle uses a precision rolling bearing combination with a three-point support structure, ensuring stable operation under heavy loads.

The saddle guideways are equipped with PTFE soft strips to reduce friction and improve feed performance. The tailstock spindle is designed to be a rotatable structure, reducing wear and heat generation of the live center.

Key Features:

Heavy Load Capacity:

Capable of handling workpieces with up to 16 tons of weight, making it ideal for machining large and heavy components.Rectangular Guide Rails:

The rectangular guide rail design provides excellent stability and rigidity, ensuring smooth operation during heavy-duty machining tasks.High-Rigidity Bed:

The bed guideways undergo medium-frequency quenching and grinding to ensure high wear resistance, accuracy, and performance under heavy machining loads.Precision Spindle:

The machine’s precision spindle is supported by high-precision rolling bearings in a three-point support structure, providing consistent rotation stability for both rough and finish cutting operations.Reduced Friction:

The PTFE soft strips on the saddle guideways reduce friction and enhance the machine’s dynamic characteristics, improving the overall performance and accuracy of the feed system.Rotatable Tailstock Spindle:

The rotatable tailstock spindle reduces wear and heat generation of the live center, extending the service life of the machine.

Machining Capabilities:

Turning Operations:

The machine is capable of turning a wide variety of parts, including end faces, outer circles, inner holes, and threads (both metric, imperial, modular, and taper threads).Taper Turning:

It can perform short taper turning using the top tool holder alone, and long taper turning using the large tool holder in combination with the longitudinal feed.Other Machining Operations:

In addition to turning, the machine can also handle operations such as drilling, boring, and grooving.

Power and Durability:

The machine’s high power and rigid structure enable it to perform demanding machining tasks with high precision. It can be equipped with hard alloy tools for thread cutting, making it suitable for processing various ferrous and non-ferrous metals.

Applications:

Heavy Machinery: Perfect for machining large, heavy components such as machine parts, turbine components, and heavy-duty shafts.

Automotive Industry: Ideal for turning engine blocks, transmission parts, and other vehicle components.

Energy Sector: Suitable for machining turbine shafts, pumps, and compressors used in power generation.

General Manufacturing: Used in a wide range of industries for turning large and complex parts that require high precision and durability.

The C61125/61160/61180/61200 heavy-duty machine tool series offers excellent performance, stability, and versatility for high-capacity turning and machining tasks, making it an ideal solution for industries dealing with large and heavy parts.

Video

Parameter

| ITEM | UNIT | C61125 | C61160 | C61180 | C61200 |

| CAPACITIES | |||||

| Swing over bed | mm | 1250 | 1600 | 1800 | 2000 |

| Swing over carriage | mm | 900 | 1250 | 1450 | 1650 |

| Max.length of workpiece | mm | 3000 4000 5000 6000 8000 10000 12000 | |||

| Max.turning length | mm | 2800 3800 4800 5800 7800 9800 11800 | |||

| Pan of guideway | mm | 1100 | |||

| SPINDLE | |||||

| Spindle nose | mm | A2-15 | |||

| Spindle bore | mm | 100 | |||

| Taper hole of spindle | Metric140 | ||||

| Range of spindle speeds | r/min | Forward:3.15~315; Reverse:3.5~291 | |||

| No.of spindle speeds | r/min | Forward:21 ; Reverse:12 | |||

| FEED | |||||

| No.of Longitudinal and cross | 56/56 | ||||

| Feed per revolution | mm | Longitudinal:0.1~12;Transverse:0.05~6;Up turret:0.025~3 | |||

| No. and range of metric thread | 44;1~120mm | ||||

| No. and range of inch thread | 31;28~1/4″ | ||||

| No. and range of module thread | 45;0.5~60mm | ||||

| No. and range of dia. thread | 38;1/2~56DP | ||||

| TURRET | |||||

| Distance of centerline and tool resting plane | mm | 53 | |||

| Tool post swing range | ° | ±90° | |||

| Max.travel of cross slide | mm | 740 850 900 900 | |||

| Max.travel of top slide | mm | 360 | |||

| Section of tool shank | mm | 50(380×380) | |||

| Travel of tool post (per turn of dials) | mm | 0.05(0.002″) | |||

| TAILSTOCK | |||||

| Dia. of tailstock | mm | 260 | |||

| Travel of tailstock quill | mm | 300(12″) | |||

| Taper hole of tailstock quill | Metric80 | ||||

| OTHERS | |||||

| Main motor power | kw | 30 | |||

| Length | mm | 6120 7120 8120 9120 11120 13120 15120 | |||

| Width | mm | 2058 2130 2330 2430 | |||

| Height | mm | 2200 2380 2480 2580 | |||

| Max.weight of workpiece | t | 16 | |||