Description

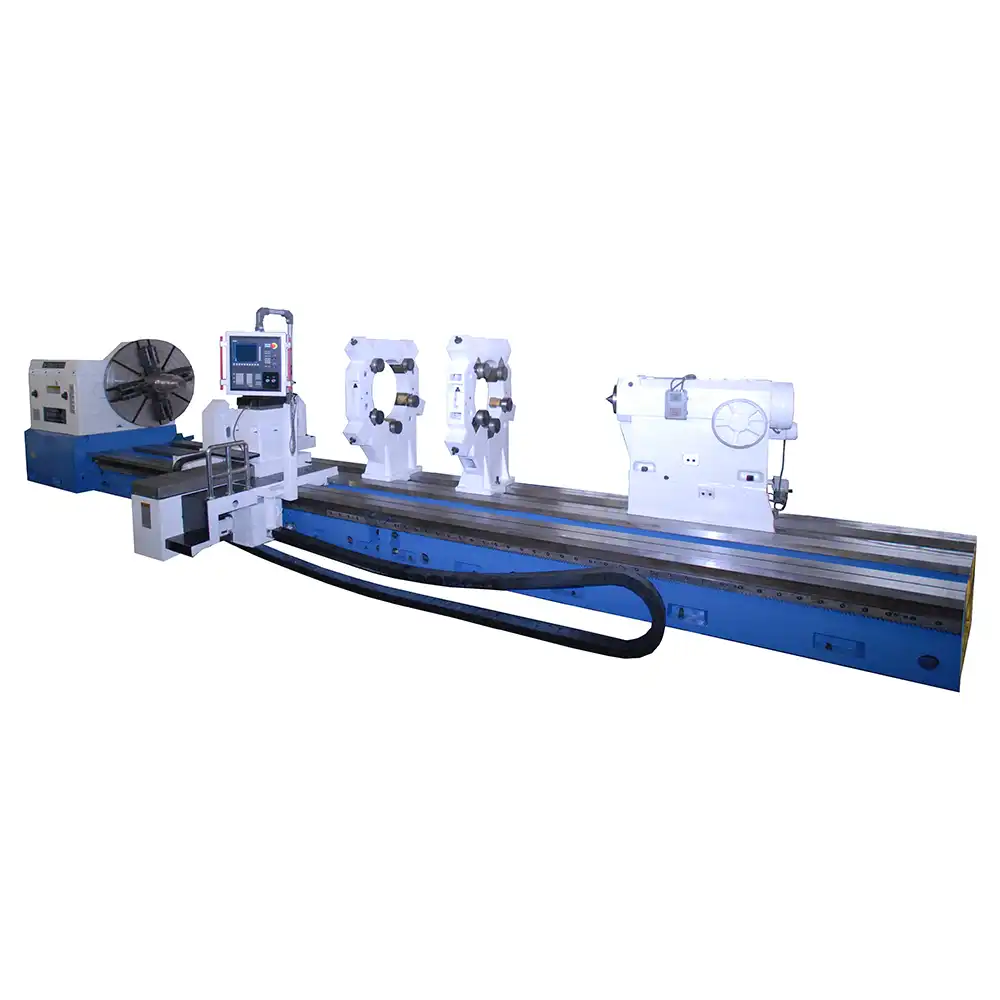

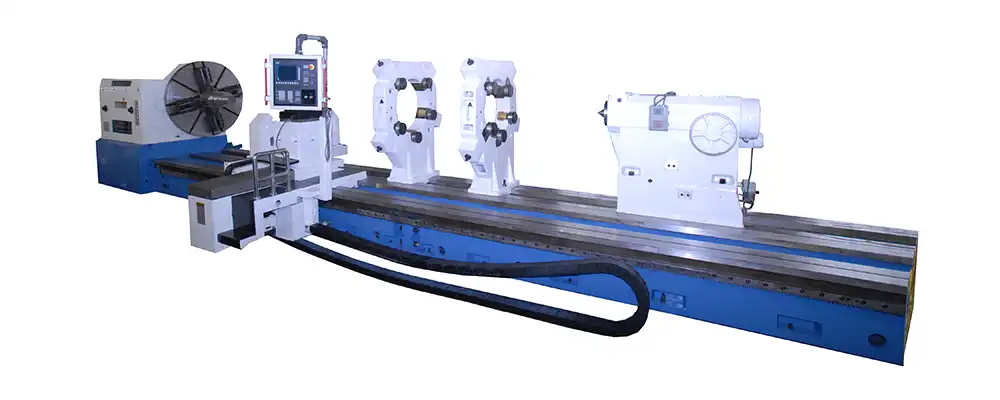

CK61160/200/250(32/63) Heavy Duty Horizontal Lathe

The machine is designed for a load capacity of 32 tons and 63 tons. It is suitable for high-speed steel and carbide tools to process different materials such as shaft parts, cylindrical, and disc-shaped components. The machine is capable of turning external diameters, end faces, grooving, parting, boring holes, turning and boring internal and external tapers, as well as cutting various threads.

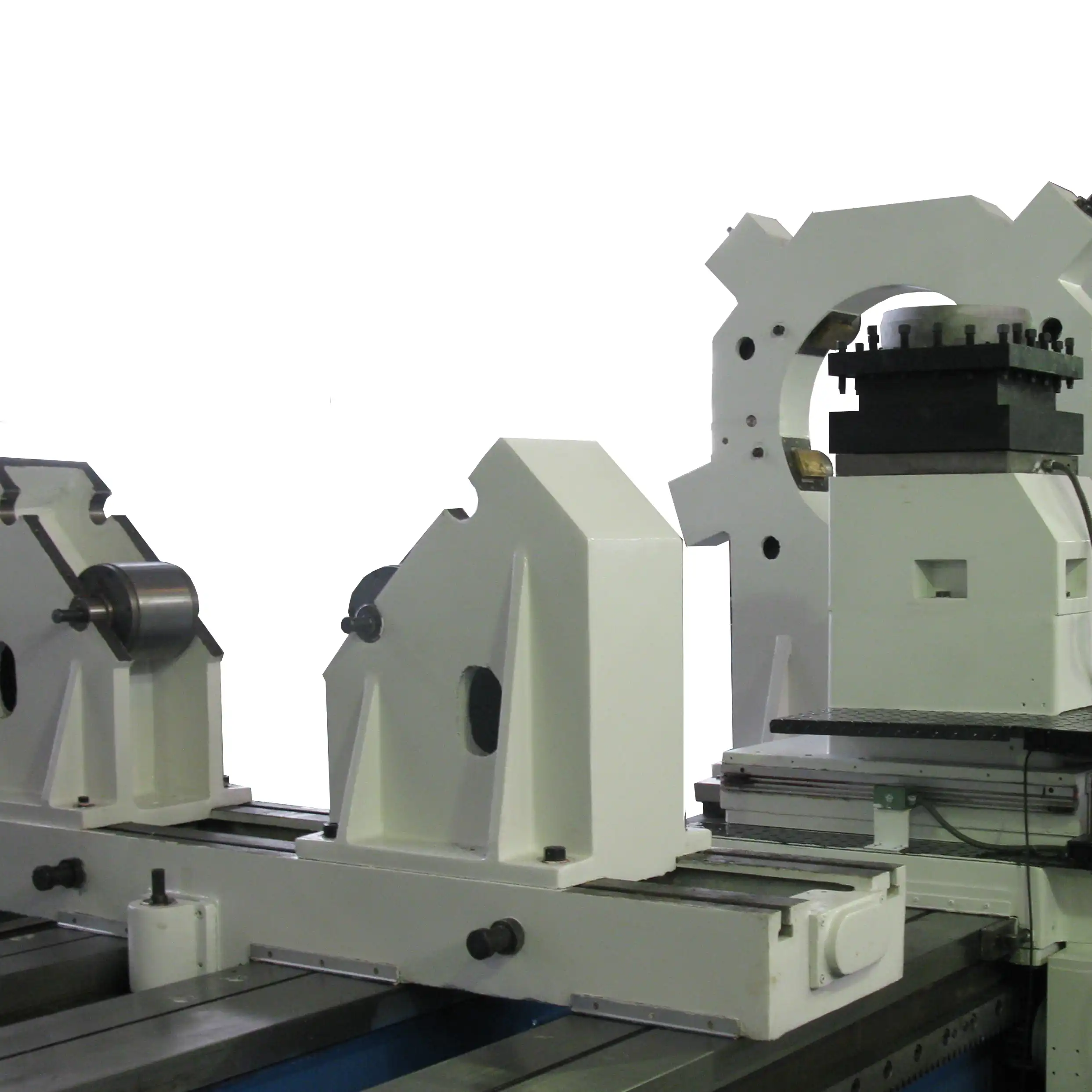

Bed Construction: The bed is made of an integrated box-shaped structure with three rectangular guide rails, cast in high-grade cast iron (HT300) in one piece, followed by secondary aging treatment for stability. The guide rail surfaces are wide (1600mm/2090mm), providing high rigidity and strong vibration resistance. The rails are fitted with steel liners and precisely ground using imported guide rail grinding machines, ensuring long service life, high precision, and excellent retention.

Main Drive System: The main drive is powered by a 75/144kW DC motor, utilizing a magnetic adjustment and voltage control mixed speed regulation system. The total speed range is 1:22.2 (1:39.58), with three speed levels (four levels for the 63-ton version). The combined mechanical and electrical speed adjustment ratio is 1:200 (1:266), providing the spindle with a stepless speed range of 0.8 to 160 rpm (0.5 to 125 rpm).

Feed Systems:

The Z-axis feed system uses imported precision gear rack structures for high accuracy.

The X-axis feed system uses a high-precision ball screw, ensuring the stability of machining accuracy.

Parameter:

| ITEM | UNIT | CK61160 | CK61200 | CK61220 | CK61250 |

CAPACITIES | |||||

| Swing over bed | mm | 1600 | 2000 | 2200 | 2500 |

| Swing over carriage | mm | 1250 | 1600 | 1850 | 2200 |

| Max.length of workpiece | mm | 4000~20000 | 10000 | ||

| Max.weight of workpiece | t | 32 | 63 | ||

| Form of bed guideway | 3 GUIDEWAY | ||||

| Span of guideway | mm | 1600 | 2090 | ||

SPINDLE | |||||

| Power of spindle | kw | 75 | 144 | ||

| Center cone apex angle | ° | 75 | 75 | ||

| Spindle speed | STEPLESS | STEPLESS | |||

| Range of spindle speed | r/min | 0.8~160 | 0.5~125 | ||

| Face chuck Dia. | mm | 1600/1800 | 2200 | ||

| Max.torque of face chuck | knm | 80 | 120 | ||

| FEED | |||||

| Range of cross feed | mm/min | 1~2000 | 1~3000 | ||

| Travel of cross | mm | 725 | 1000 | ||

| Range of longitudinal feed | mm/min | 1~4000 | 1~6000 | ||

| Travel of longitudinal | mm | 4000~20000 | 10000 | ||

TURRET | |||||

| Turret working pistion | V4 | box-type | |||

| Size of turret | mm | 70X70 | 80X80 | ||

| Max.cutting force | kn | 80 | 120 | ||

| Rapid of turret | kw | 1.5 | 4 | ||

TAILSTOCK | |||||

| Dia. of tailstock | mm | 300 | 560 | ||

| Travel of tailstovk | mm | 300 | 200 | ||

| Taper hole of tailstock | 100/1:7 | 160/1:4 | |||

| Rapid of tailstock | mm/min | 3000 | 2500 | ||

| Rapid of sleece | mm/min | 664 | 50 | ||

OTHERS | |||||

| Length | mm | 15580 | 18475 | ||

| Width | mm | 3500 | 3622 | ||

| Hight | mm | 2280 | 3250 | ||

| Weight | kg | 48000 | 118000 | ||

| CNC system | 0i-TD(Optional Siemens) | ||||