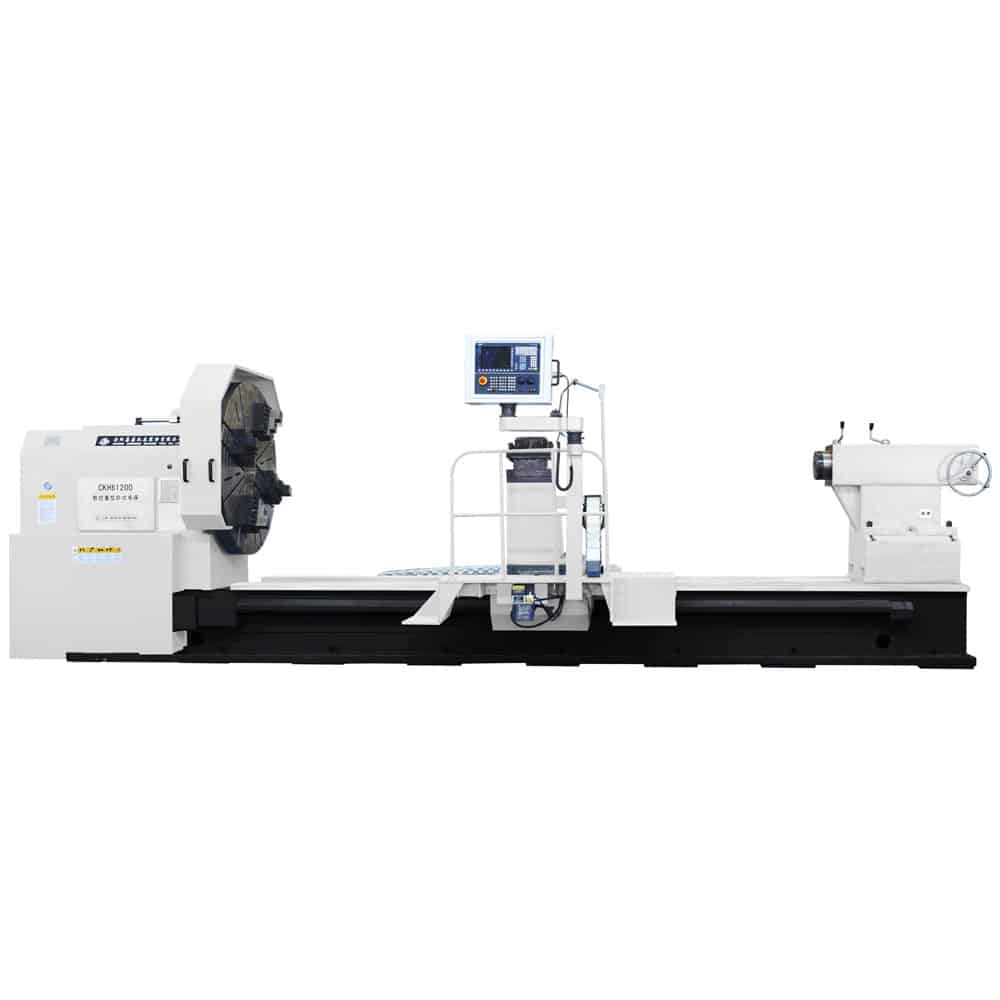

CKH(J) 61125/160/200 heavy-duty CNC lathe

Max capable of handling workpieces weighing up to 16,000 kg

Guideway width of 1100mm

Description

The CKH(J) 61125/160/200 series heavy-duty CNC lathe is a high-performance machine with a wide range of applications and notable advantages. Its semi-closed-loop control system and 16-ton load-bearing capacity make it ideal for machining complex parts in various shapes. Below are its main structural features:

Bed Structure:

The bed is an integrated box-type structure made of high-grade cast iron (HT300), cast in one piece and subjected to secondary aging treatment, ensuring strength and stability.

The guideways have a width of 1100 mm, enhancing the machine’s load-bearing capacity and stability.

Spindle Box:

The box-type structure provides high rigidity, suitable for heavy-duty cutting operations.

The spindle gears are subjected to high-frequency quenching and precision grinding, ensuring high accuracy, smooth operation, and low noise.

The large spindle diameter is supported by precision heavy-duty bearings in a three-point support configuration, providing stable rotation for both heavy cutting and precision turning.

The automatic forced circulation lubrication system ensures smooth operation of the transmission system and effective cooling.

The machine supports stepless speed regulation and constant linear speed cutting, accommodating various machining needs.

Feed System:

The Z-axis sliding guideways are equipped with TSF soft strips, greatly reducing the friction coefficient and improving servo response performance.

The X-axis feed is driven by an AC servo motor connected to the ball screw through a flexible coupling, ensuring high machining accuracy, positioning precision, and accuracy retention.

The machine features an automatic lubrication system for all motion pairs, which ensures proper lubrication during operation.

For longitudinal (Z-axis) feed, the system uses an AC servo motor and high-precision planetary gearbox, ensuring stable and precise feed motion.

This heavy-duty CNC lathe is not only highly accurate in machining and repeat positioning but also performs efficiently and stably under heavy-load conditions, making it ideal for machining complex parts. It is widely used in industries such as aerospace, shipbuilding, metallurgy, and petrochemical industries.

Parameter

| ITEM | UNIT | CKH/CKHJ61125 | CKH/CKHJ61160 | CKH/CKHJ61200 |

| CAPACITIES | ||||

| Swing over bed | mm | 1250 | 1600 | 2000 |

| Swing over carriage | mm | 900 | 1250 | 1600 |

| Max.length of workpiece | mm | 3000 5000 6000 8000 10000 12000 | ||

| Max.turning length | mm | 2800 4800 5800 7800 9800 11800 | ||

| Pan of guideway | mm | 1100 | ||

| SPINDLE | ||||

| Spindle nose | mm | A2-15 | ||

| Spindle bore | mm | 100 | ||

| Taper hole of spindle | Metric 140 | |||

| Range of spindle speeds | r/min | CKH:3~320;CKHJ:forward3.15~315/reverse3.5~291 | ||

| No.of spindle speeds | CKH:Stepless CHHJ:Manual 21/12 | |||

| Max.weight of workpiece | t | 16 | ||

| Chuck | mm | 1250 | 1400 | 1600 |

| FEED | ||||

| Max.cutting power | N | 39200 | ||

| Rapid speeds | mm/min | 4000/6000 | ||

| Max.travel | mm | 850 | ||

| TURRET | ||||

| Turret working position | V4 | |||

| Size of turret | mm | 380×380 | ||

| Max.feed force Py | N | 10875 | ||

| Section of tool shank | mm | 50×50 | ||

| TAILSTOCK | ||||

| Dia. of tailstock quill | mm | 260 | ||

| Travel of tailstock quill | mm | 300 | ||

| Taperhole of tailstock | Metric 80 | |||

| OTHERS | ||||

| Workpiece accuracy | IT7 | |||

| Surface roughness | μm | Ra2.5~3.2 | ||

| Main power | kw | 30 | ||

| Lathe mass | kg | CKH61125:1500 19400 21560 26000 30400 34800 | ||

| Length | mm | 6400 8400 9400 11400 13400 15400 | ||

| Width | mm | 3200 | ||

| Height | mm | 2220 | 2750 | 2950 |

| CNC System | 0i-TD | |||