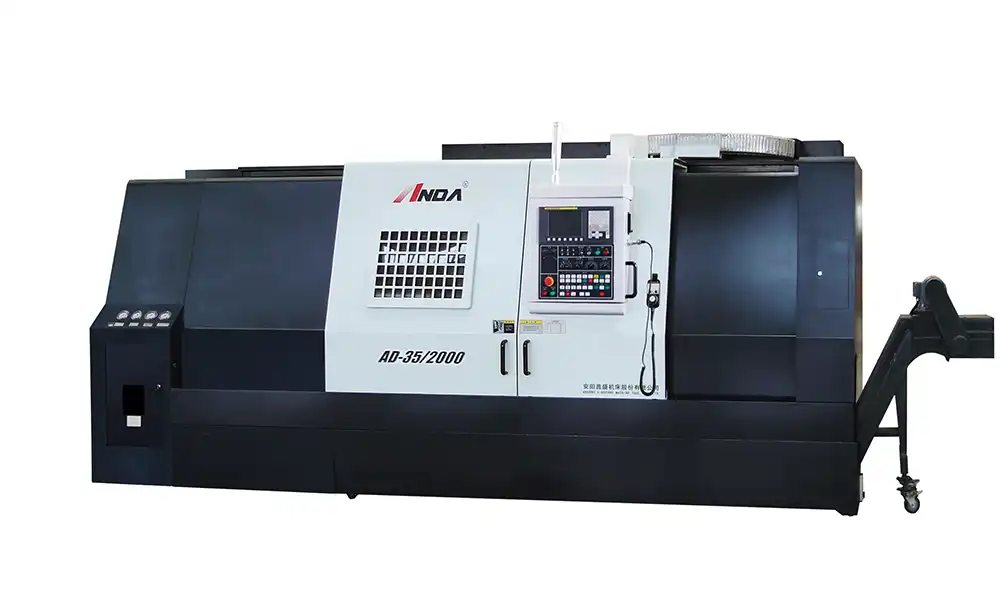

Slant Bed CNC Lathe

The AD Series Slant Bed CNC Lathe is a high-speed, precision CNC machining equipment developed using advanced Japanese technology. It is suitable for machining various complex-shaped shaft, sleeve, and disc-type components. Typical operations include turning of internal and external cylindrical surfaces, conical surfaces, arc surfaces, end faces, as well as grooving, chamfering, drilling, reaming, and threading.

Description

Slant Bed CNC Lathe

The AD Series Slant Bed CNC Lathe is a high-speed, precision CNC machining equipment developed using advanced Japanese technology. It is suitable for machining various complex-shaped shaft, sleeve, and disc-type components. Typical operations include turning of internal and external cylindrical surfaces, conical surfaces, arc surfaces, end faces, as well as grooving, chamfering, drilling, reaming, and threading.

Main Structural Features:

Base and Bed Structure:

The base and bed adopt a box-type structure and are cast using integrated molding technology. Precision machining is completed in a single clamping process on a five-face machining center, ensuring excellent dimensional stability and long-term accuracy retention.Slant Bed Design:

A high-rigidity 45° slant-bed design is adopted. The slideway surfaces utilize plastic-bonding technology to optimize the dynamic and static performance of the feed system, including rigidity and friction resistance. The design includes a separate coolant tank to prevent leakage and facilitate maintenance.Hydraulic Turret:

Equipped with a hydraulic tool turret, the tool holders are interchangeable at all turret positions. The turret supports bi-directional indexing for the nearest tool change path, enabling fast, smooth, and reliable tool change operations.High-Rigidity Spindle Structure:

The headstock features a gearless design to minimize noise and vibration. The spindle assembly provides high rigidity to ensure machining stability and surface quality.Hydraulic Chuck and High-Speed Cylinder:

The machine is equipped with a hydraulic chuck and high-speed hydraulic cylinder, controlled via a foot switch, allowing convenient, safe, and reliable workpiece clamping.Precision Feed Transmission:

Both X and Z axes use large-diameter, high-precision ball screws with pre-tensioning and pre-loading. High-precision angular contact ball bearings are mounted at both ends to ensure excellent motion and positioning accuracy.Safety and Protection:

The lathe features a fully enclosed guard, electrical cabinet safety devices, and a safety interlocked operation door. The operation door is fitted with reinforced glass to ensure the safety of both the machine and the operator.

Parameter:

| Item | Unit | AD10 | AD15B | AD25 | AD35 | AD35B | AD45 |

| CAPACITIES | |||||||

| Swing over bed | mm | 450 | 500 | 600 | 700 | 700 | 850 |

| Max. dia. cutting | mm | 300/260 | 320/320 | 420/420 | 550/500 | 550/500 | 800/650 |

| Max.workpiece length | mm | 600/1100 | 600/1100 | 625/1000/1500/2000/3000 | 890/1640/2000/3000 | 1640 | 1500/2000/3000 |

| Max. turning length | mm | 450/950 | 450/950 | 530/905/1405/1905/2905 | 780/1530/1890/2890 | 1530 | 1420/1920/2920 |

| FEED | |||||||

| x-axis travel | mm | 170 | 190 | 230 | 305 | 335 | 450 |

| z-axis travel | mm | 460/960 | 460/960 | 590/965/1465/1965/2965 | 865/1605/1965/2965 | 1605 | 1450/1950/2950 |

| Rapid travel of x | 18 | 18 | 12 | 12 | 12 | 12 | |

| Rapid travel of z | 20 | 20 | 15 | 15 | 12 | 15 | |

| X/Z feed speed | 1260 | 1260 | 1260 | 1260 | 1260 | 1260 | |

| SPINDLE | |||||||

| Spindle speed | rpm | 50-4500 | 45-4000 | 35~3500 | 25~2500 | 25~1000 | 10~2000 |

| Spindle power | kw | 7.5 | 11 | 18.5/15 | 30/22 | 22 | 100 |

| Spindle nose | A2-5 | A2-6 | A2-8 | A2-8 | A2-11 | A2-11 | |

| Spindle bore(Dia.) | mm | 50 | 62 | 87 | 92 | 92 | 131 |

| Size of chuck | inch | 6 | 8 | 10 | 12 | 12 | 15/18 |

| Front bearing dia. | mm | 80 | 100 | 130 | 160 | 160 | 200/240 |

| TOOL POST | |||||||

| NO. of stations | 8 | 8 | 12 | 12 | 12 | 12 | |

| Indexing time | s | 0.58 | 0.58 | 0.3 | 1 | 1 | 1 |

| Size of turret | mm | 20X20 | 25X25 | 25X25 | 25X25 | 32X32 | 32X32 |

| Dia. of bar shank | mm | 32 | 40 | 40 | 50 | 60 | 60 |

| TAILSTOCK | |||||||

| Max. travel | mm | 360 | 360/860 | 490/865/1365/1865/2865 | 706/1456/1816/2816 | 1456 | 1400/1900/2900 |

| Quill Dia | mm | 80 | 80 | 85 | 110 | 110 | 140 |

| Quill taper hole | MT-4 | MT-4 | MT-5 | MT-5 | MT-5 | MT-6 | |

| Quill travel | mm | 100 | 100 | 80 | 100 | 100 | 130 |

| OTHERS | |||||||

| Main power | kw | 20 | 25 | 30 | 46 | 50 | 130 |

| Weight | t | 3.5/4.5 | 3.6/4.8 | 5/5.5/6.5/7.5/8.5 | 8/10.1/11.5/15.5 | 10 | 15/16/18 |

| Length | mm | 2575/3470 | 2575/3470 | 3000/3380/4550/4960/6160 | 3620/4725/5825/7000 | 5614 | 6360/6860/7860 |

| Width | mm | 1485 | 1485 | 1545 | 1820 | 2031 | 2350 |

| Hight | mm | 1700 | 1700 | 1950 | 2130 | 2147 | 2600 |

| Accuracy/roughness | μm | IT6/Ra0.8 | IT6/Ra0.8 | IT6/Ra0.8 | IT6/Ra0.8 | IT6/Ra0.8 | IT6/Ra1.6 |

| CNC system | FANUC 0i-TF (Other systems can be optionally selected as needed) | ||||||