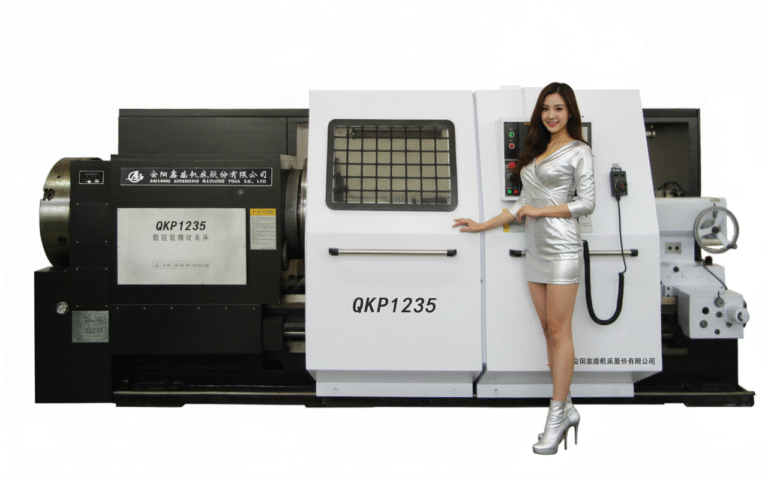

Comparison of Anyang Xinsheng CNC Lathes and Ordinary Lathes

In general, the CNC lathes from Anyang Xinsheng Machine Tool Co., Ltd. have the advantages of an advanced structure, good performance, convenient operation, and a neat and beautiful appearance. Specifically: The machine tool has a beautiful and elegant appearance, with a reasonable layout, compact structure, and is convenient for chip removal. The machine tool possesses…