General Machining Guidelines for Turning Operations

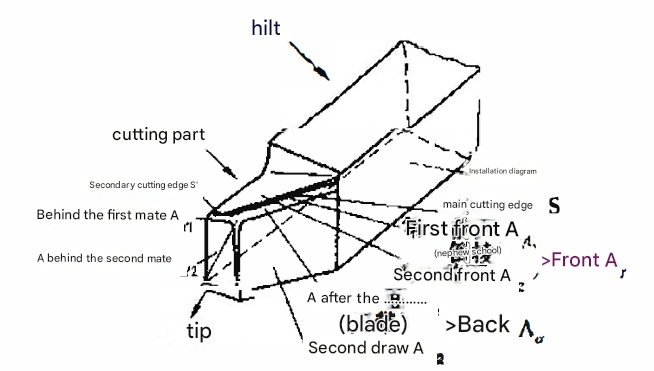

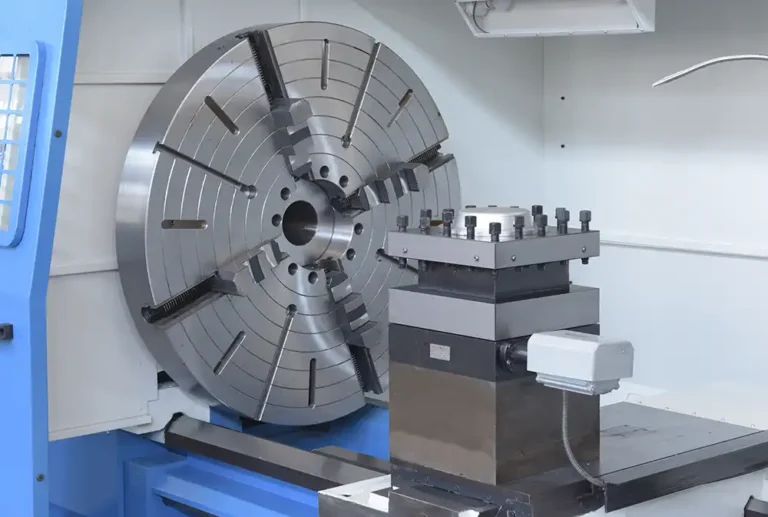

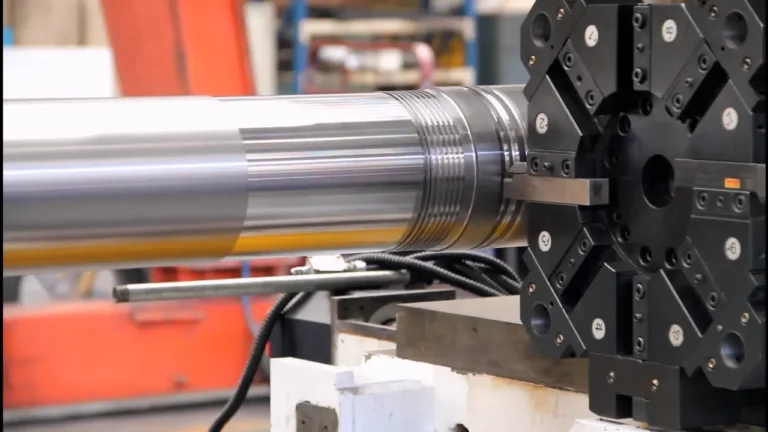

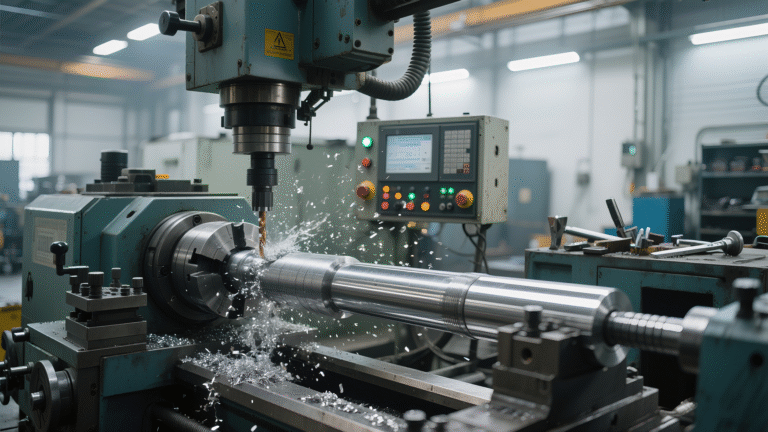

Tool Clamping The length of the tool shank extending from the tool holder should not exceed 1.5 times the height of the tool shank (except for boring, grooving, etc.). The tool shank axis should be perpendicular or parallel to the feed direction. Adjustment of Tool Tip Height: For turning end faces, conical surfaces, threads, forming…