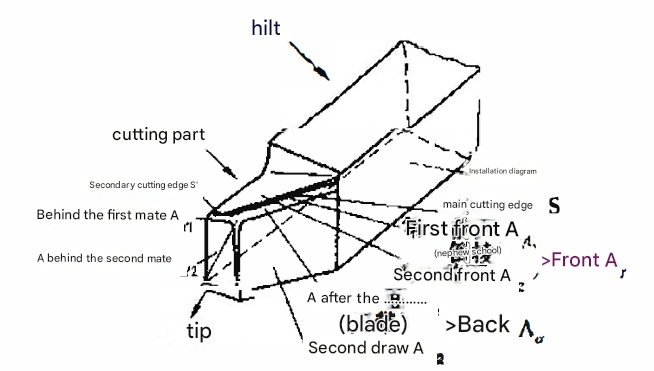

Describe the names, symbols, and definitions of the cutting point and faces of a lathe cutting tool.

The cutting edges, points, and faces of the lathe tool are shown in Figure Their names, symbols, and definitions are provided in the figure Symbols and Definitions of Edges, Points, and Faces on a Turning Tool’s Cutting Portion Term Symbol Definition Shank The clamping part of the tool. Mounting Face A surface on the shank…