CK6150 CNC lathe

Exploring the CK6142/52, CKJ6142/52, and CKP6142/52 Series CNC Lathes: A Perfect Blend of Affordability, Performance, and Versatility

When it comes to precision machining, the CK6142/52, CKJ6142/52, and CKP6142/52 series CNC lathes stand out as a reliable solution. These machines combine solid engineering with user-friendly features, offering exceptional value to businesses in various industries such as automotive, petroleum, and defense manufacturing. Let’s dive into what makes this series a go-to choice for versatile and efficient machining.

High Performance Meets Affordability

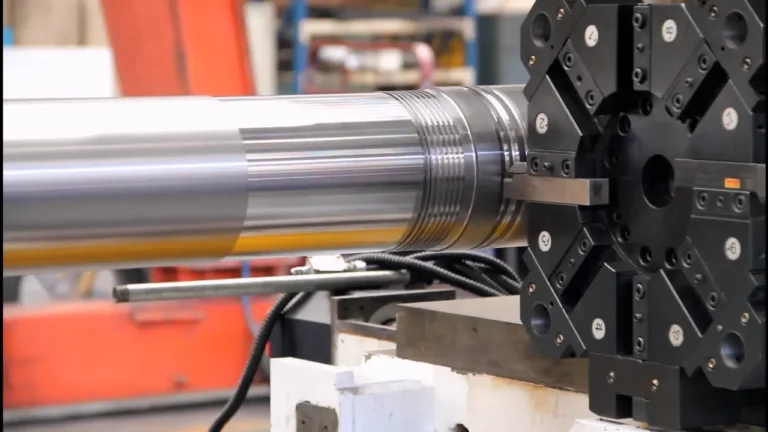

The CK series lathes are designed for high efficiency, low scrap rates, and excellent consistency. Their versatility makes them ideal for processing a wide range of parts, including complex shafts, sleeves, discs, and other detailed components. They are perfect for internal and external surface turning, as well as operations on conical surfaces, arcs, threads, and hole drilling, expansion, and reaming processes. This flexibility allows users to handle various small to medium-sized production runs with ease.

The CK series CNC lathes are known for their mature structure and stable performance. They are economical yet packed with features that ensure precision and ease of use, especially in environments that require quick turnaround times and reliable output.

Enhanced Functionality Across Models

While the CK6142/52, CKJ6142/52, and CKP6142/52 share several core features, there are subtle differences in their operations that cater to different user needs.

- CK Series: These models come with variable frequency and hydraulic four-speed automatic conversion, which allows the spindle to achieve infinitely variable speed throughout the range. This feature is perfect for maintaining constant cutting speed and high torque at low speeds, ensuring a smooth operation even in demanding cutting scenarios.

- CKJ Series: These machines feature manual gear shifting, providing 12 distinct speed levels. This option is ideal for users who prefer a more hands-on approach to speed control, offering flexibility in adapting to different machining requirements.

- CKP Series: With variable frequency control and a four-speed manual shifting system, the CKP models provide a segmented, infinitely variable speed adjustment, combining the benefits of automated control with the precision of manual operation.

Precision and Stability

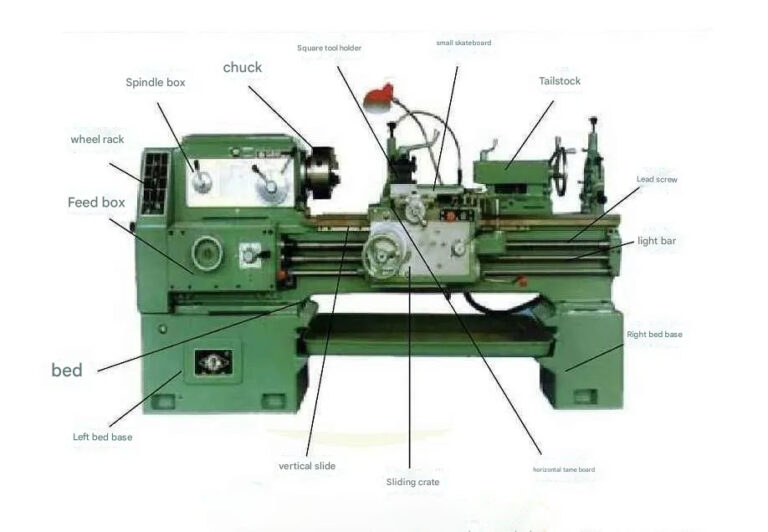

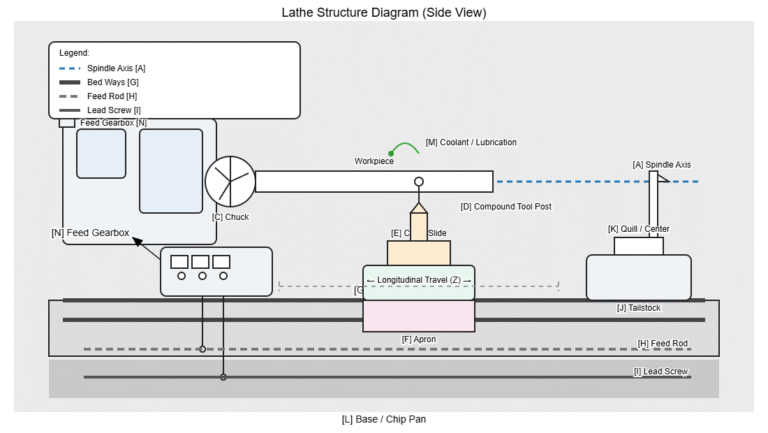

The foundation of these lathes is their sturdy, integrated bed structure. The wide 400mm bed guide rail ensures excellent rigidity, helping the machine maintain its precision even during heavy-duty machining operations. This robust design contributes to high-quality results, reducing wear and tear and minimizing the chances of machine vibration during cutting.

The main drive system utilizes a frequency-controlled motor and hydraulic four-speed gear system. This combination allows for continuous and smooth speed adjustment, enabling efficient machining even at low speeds with high torque.

For added precision, the feed system is driven by a servo motor that operates on a ball screw, delivering high transmission accuracy. The tool post, with its end-tooth disc positioning, ensures superior repeatability and rigidity.

Modular Design and Customization

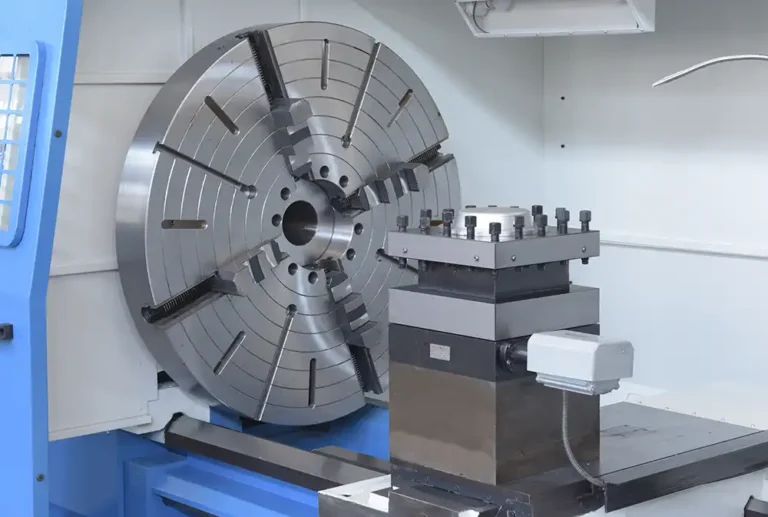

One of the standout features of the CK, CKJ, and CKP series is their modular design. Users can customize their machines to meet specific operational requirements. Whether it’s adding a manual, electric, or hydraulic chuck, or choosing between a manual or hydraulic tailstock, the machines can be tailored for optimal performance. Additionally, the tool posts come in different configurations, including vertical four-position, vertical six-position, and horizontal six-position setups.

Advanced Control Systems

The machines in this series are equipped with some of the most advanced CNC control systems in the world. With options from renowned brands like FANUC (Japan) and SIEMENS (Germany), users benefit from high-quality control that ensures smooth and efficient operation. These systems also make programming easier and more intuitive, allowing even operators with minimal experience to perform complex tasks with confidence.

Protection and Safety Features

The CK series lathes offer two types of protection: full protection and semi-protection. This design provides operators with different levels of safety depending on their specific needs and operational environment. The machines are also designed with an integrated electrical, mechanical, and hydraulic system, streamlining the layout and reducing maintenance needs.

Wide Application in Various Industries

Due to their superior precision and adaptable features, these CNC lathes are widely used in various industries. They are particularly effective in manufacturing parts for sectors such as:

- Automotive: Precision machining of engine components, drive shafts, and other mechanical parts.

- Petroleum: Creating parts for oil extraction, refining equipment, and pipelines.

- Military and Aerospace: Crafting intricate components that require high levels of reliability and precision.

Conclusion

The CK6142/52, CKJ6142/52, and CKP6142/52 CNC lathes offer a perfect balance of cost-effectiveness and high performance. With their versatility, stability, and ease of use, these machines are ideal for industries that require high-precision machining for complex parts. Their modular design, advanced control systems, and customizable configurations make them an excellent choice for businesses looking to enhance their production capabilities without compromising on quality.

If you’re in the market for a CNC lathe that provides excellent value, the CK series is a solution worth considering.