Cutting depth (ap), S, and F are the three main cutting parameters in lathe machine

On a lathe machine, the terms cutting depth (ap), S, and F are the three main cutting parameters you must know.

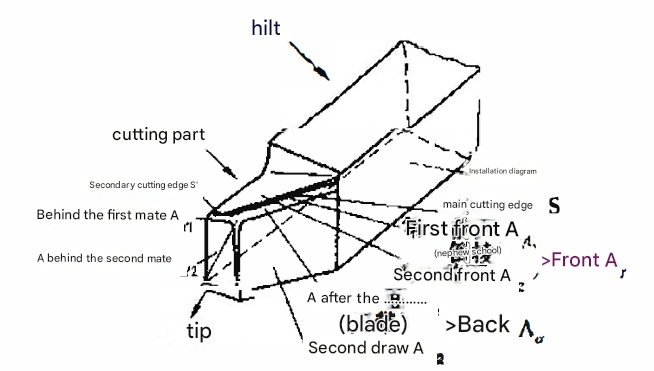

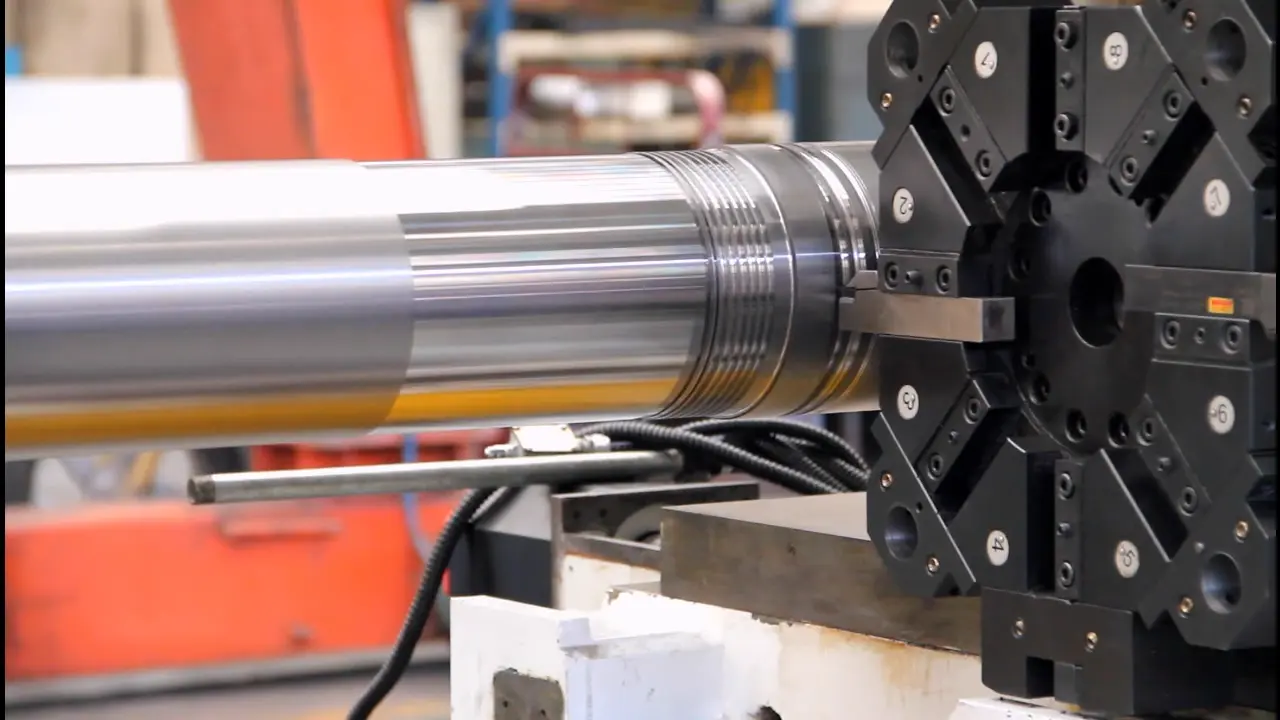

1. Depth of Cut (ap)

Meaning: How deep the tool cuts into the workpiece in one pass.

Unit: millimeters (mm).

Typical values:

Roughing (removing material fast) → 2–5 mm

Finishing (for smooth surface) → 0.2–0.5 mm

👉 Example: If depth of cut = 2 mm, the tool removes a 2 mm layer from the diameter of the workpiece.

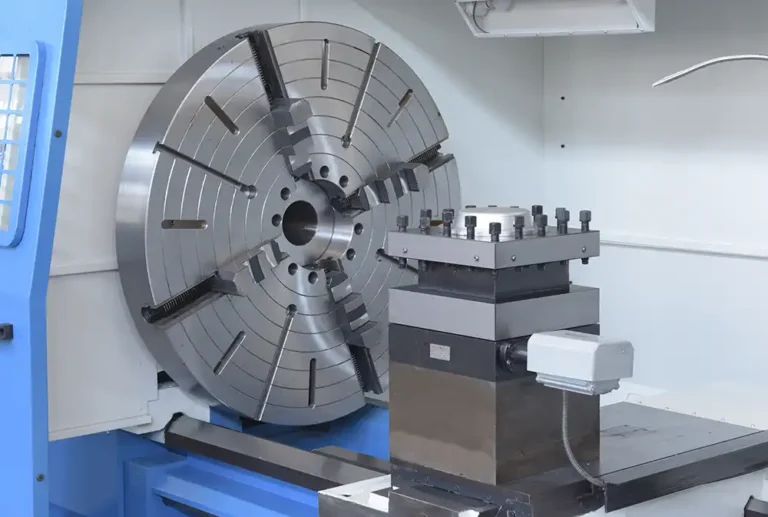

2. S (Spindle Speed)

Meaning: How fast the workpiece rotates in the spindle.

Unit: revolutions per minute (r/min or RPM).

Formula:

n=1000×vπ×dn = \frac{1000 \times v}{\pi \times d}

where:

v = cutting speed (m/min)

d = workpiece diameter (mm)

👉 Example: If cutting speed = 100 m/min and workpiece diameter = 50 mm:

n=1000×1003.14×50≈636 RPMn = \frac{1000 \times 100}{3.14 \times 50} \approx 636 \, \text{RPM}

3. F (Feed Rate)

Meaning: How far the tool moves forward along the workpiece for each spindle revolution.

Unit: mm/rev (millimeters per revolution).

Typical values:

Roughing → 0.3–0.6 mm/rev

Finishing → 0.05–0.2 mm/rev

👉 Example: If feed = 0.2 mm/rev and spindle speed = 600 RPM, then feed per minute =

0.2×600=120 mm/min0.2 \times 600 = 120 \, \text{mm/min}

✅ In summary:

Depth of cut (ap) = how deep the tool cuts

S (Spindle speed) = how fast the workpiece rotates

F (Feed rate) = how much the tool moves forward each revolution

These three parameters decide the surface finish, machining time, and tool life.