Responsibilities of a Qualified Lathe Operator

Before Starting Work

- Machine Check and Warm-up:

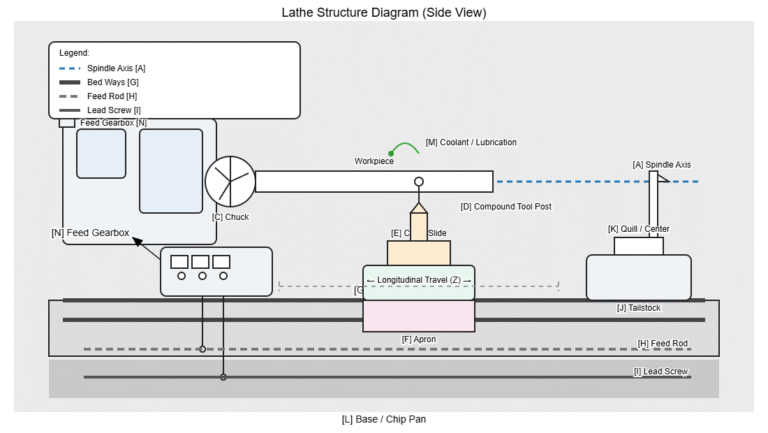

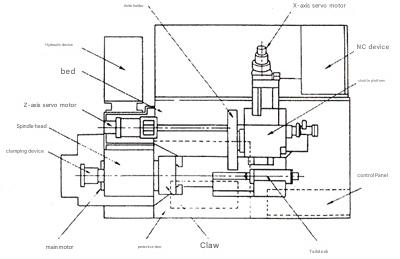

- Check whether all mechanisms of the lathe are in good condition and whether protective equipment is available. If normal, run the machine at low speed for 1-2 minutes to check if the operation is normal. This also allows the lubricating oil in the headstock to reach the relevant parts, which is especially important in winter. If the machine is abnormal, notify the repair department immediately.

- Lubrication:

- Check all oil holes and perform oiling according to the instructions on the lubrication diagram.

- Process Review:

- Familiarize yourself with the blueprint and process sheet to determine the machining method.

- Tool Preparation:

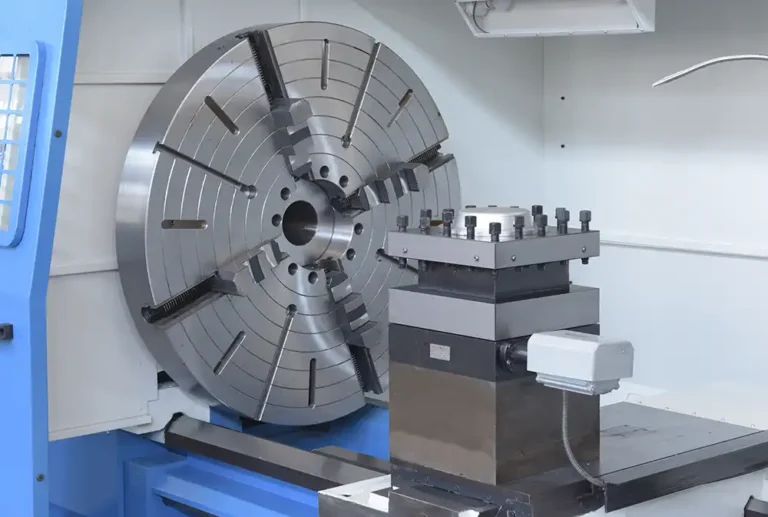

- Prepare the tools, fixtures, cutting tools, and measuring instruments.

- Blank Inspection:

- Check the workpiece blank for defects and ensure there is sufficient machining allowance.

During Work Hours

- Machine Protection and Maintenance:

- Care for the lathe; do not strike objects on the bed surface, and do not place work-holding tools or fixtures on the bed. The machine should be kept clean and lubricated regularly.

- Power Saving:

- Save electricity; do not allow the machine to run idle unnecessarily during work. Turn off the machine and lights when leaving the station.

- Speed Change Rule:

- The machine must be stopped first when changing speeds.

- Tool Management and Usage:

- Each tool should be placed in a fixed position; avoid arbitrary placement. Tools should be used according to their specific purpose and cannot be arbitrarily substituted (e.g., a steel ruler cannot substitute a screwdriver, and a wrench cannot substitute a hand file).

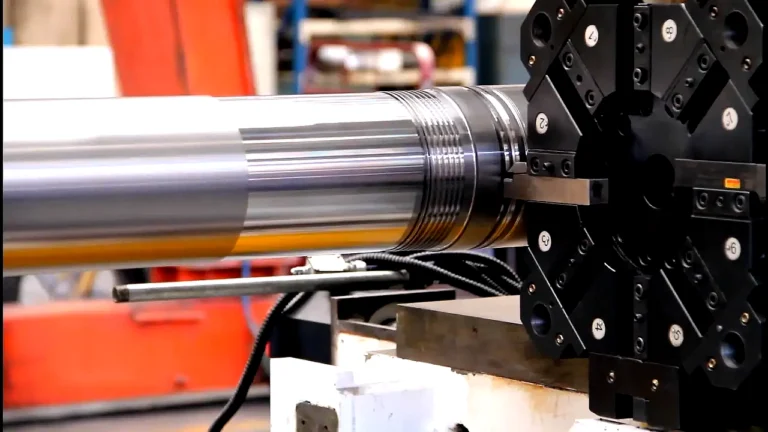

- Cutting Tool and Gauge Care:

- When a cutting tool dulls, it should be indexed or reground promptly. Do not continue cutting with a dull tool, as this increases the lathe load, can damage the machine, and reduces the quality of the processed surface. (Naturally, you should not easily discard still-usable cutting tools, which would be wasteful.)

- Care for measuring instruments, keep them clean and intact, and regularly calibrate their accuracy.

- After the first part is processed, first submit it to the inspection personnel for checking. After it is confirmed to be qualified, apply anti-rust oil before continuing to process the next part.

After Work (End of Shift)

- Item Cleaning and Storage:

- Wipe all used items clean and place them back in their original positions. Those requiring oil should be coated with a layer of anti-rust oil.

- Part Handover:

- Deliver the finished parts along with the work order to the inspection personnel. If the part is not yet finished and needs to be continued by the next shift, a clear handover must be provided.

- Tool Return:

- Return tools and fixtures that are no longer needed to the tool room.

- Machine Cleaning and Lubrication:

- Clean the lathe: Use a brush to remove the chips, then use cotton waste (or gauze) to wipe off oil stains from all parts of the machine. Finally, apply lubricating oil to all parts according to regulations.

- Accept Next Task:

- Accept the task for the next day. First, familiarize yourself with the blueprint and process, and then prepare the necessary tools, fixtures, and measuring instruments.