What are the common types and models of lathes?

Many people, whether working in the lathe industry or not, may have questions about the types and models of lathes. So, what are the common models and types of lathes? Here, Dongguan Xinhongyuan Lathe Processing Factory has compiled a collection of lathe types and models! Let’s quickly spread some knowledge about lathes!

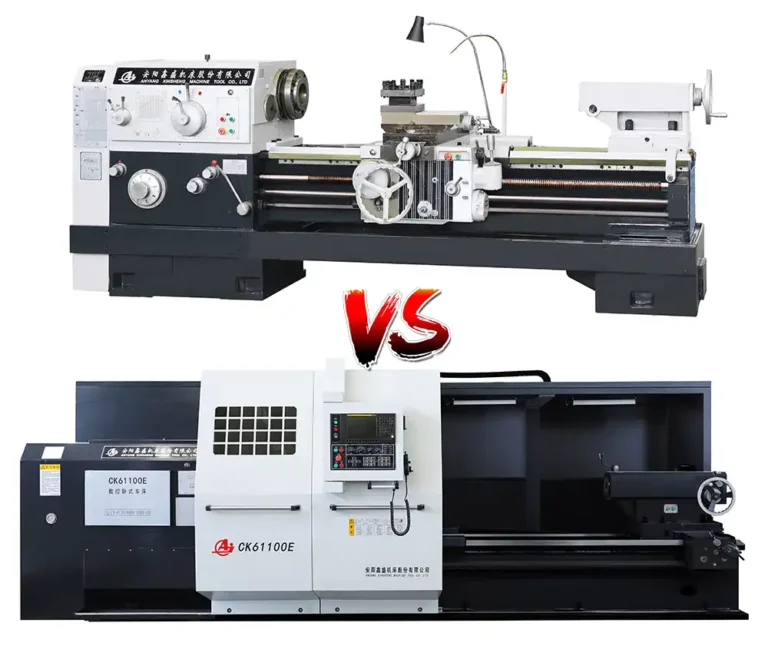

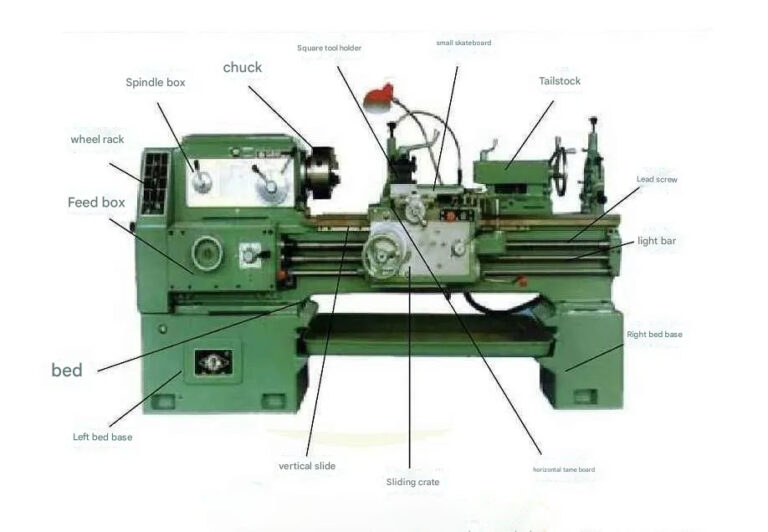

- Conventional Lathe

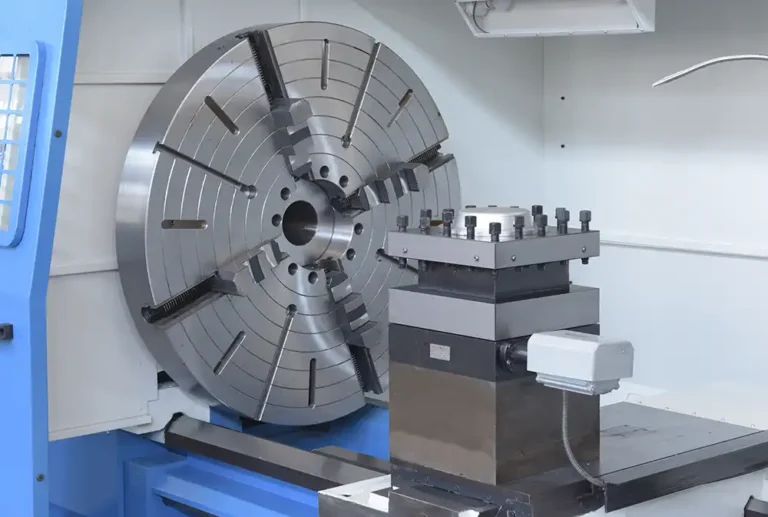

It has a wide range of processing capabilities, with large adjustable ranges for spindle speed and feed rate, and can process the internal and external surfaces, end faces, and internal and external threads of workpieces. This type of lathe is mainly operated manually by workers, with low production efficiency. It is suitable for single-piece, small-batch production and repair workshops. - Turret and Revolving Lathe

Equipped with a turret tool post or a revolving tool post capable of holding multiple tools, this lathe allows workers to use different tools sequentially to complete multiple operations with a single setup. It is suitable for mass production. - Automatic Lathe

This lathe automatically completes multi-process machining of small to medium-sized workpieces according to a set program. It can automatically load and unload parts and repeat the processing of a batch of identical workpieces. It is ideal for large-scale, high-volume production. - Multi-tool Semi-automatic Lathe

This type is available in single-axis, multi-axis, horizontal, and vertical variations. The single-axis horizontal version has a layout similar to that of a conventional lathe but with two tool posts mounted in the front and rear or top and bottom of the spindle. It is used for processing disc, ring, and shaft-type workpieces and improves productivity by 3 to 5 times compared to conventional lathes. - Profiling Lathe

This lathe can mimic the shape and dimensions of a template or sample part, automatically completing the machining cycle for the workpiece. It is suitable for small-batch and mass production of complex-shaped parts, with productivity 10 to 15 times higher than conventional lathes. There are various types, including multi-tool posts, multi-axis, chuck-type, and vertical types. - Vertical Lathe

The spindle is perpendicular to the horizontal plane, with the workpiece clamped on a horizontal rotating work table, and the tool post moves along a beam or column. It is suitable for processing larger, heavier workpieces that are difficult to mount on conventional lathes. There are single-column and double-column versions. - Gear Shaping Lathe

While turning, the tool post moves radially in a reciprocating motion, used for shaping gear tooth profiles, such as hobs and roll cutters. It is typically equipped with a grinding attachment powered by a separate motor, using a small grinding wheel to grind the tooth surfaces. - Specialized Lathe

These lathes are designed for processing specific surfaces of particular types of workpieces, such as crankshaft lathes, camshaft lathes, wheel lathes, axle lathes, roll lathes, and steel ingot lathes. - Combination Lathe

Primarily used for turning, but with additional components and attachments, it can also perform boring, milling, drilling, broaching, grinding, and other operations. This “multi-functional” lathe is suitable for repair work in engineering vehicles, ships, or mobile repair stations. - Saddle Lathe

The left end of the saddle lathe bed at the headstock is recessed, allowing for larger diameter workpieces. The lathe has a shape with higher ends and a lower middle, resembling a saddle. It is suitable for processing parts with large radial dimensions and small axial dimensions, capable of turning outer diameters, inner holes, end faces, threads, grooving, and performing drilling, boring, and reaming operations. It is particularly suited for single-piece or batch production. The saddle lathe can process larger diameter workpieces within the saddle slot, and its guides are hardened and finely ground for reliable operation. The lathe offers high power, high speed, strong rigidity, excellent precision, and low noise.

In fact, the most common lathes are the ten types listed above! After reading this, you should have a better understanding of the various lathe models and types. If this article has been helpful, don’t forget to save it for future reference!