What are the lathes other than ordinary lathes? What are the characteristics and uses of these lathes?

Types of lathes other than ordinary lathes and their characteristics and uses

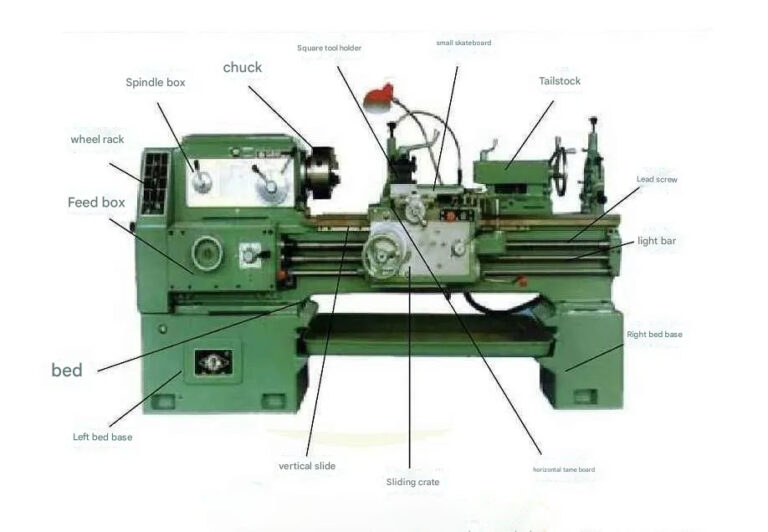

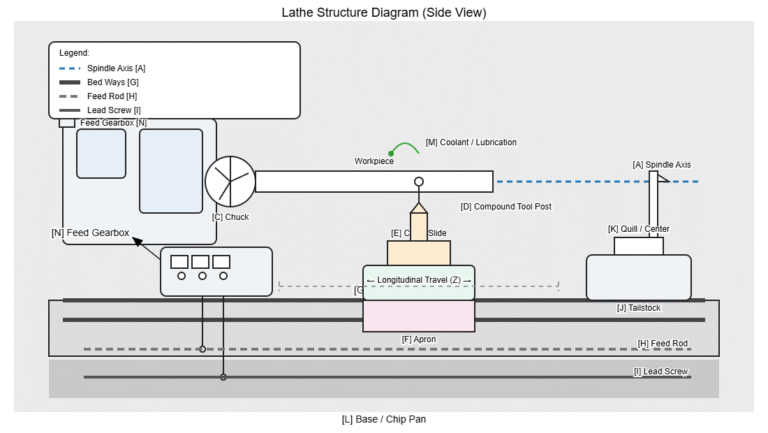

Ordinary lathe is the most widely used lathe, but in order to adapt to the processing needs of different types of workpieces, and derived from a variety of specialized lathes. They have their own focus in structure, function and application scenarios.

1. Specialized and semi-automated lathes

hexagonal lathe

Features: Uses a rotatable hexagonal tool holder instead of the traditional tailstock, allowing multiple tools to be pre-mounted.

Uses: Ideal for high volume machining of parts with center holes, increasing productivity through quick tool rotation.

multi-tool lathe

Features: Equipped with multiple tool holders (e.g. front and rear tool holders) for simultaneous cutting.

Purpose: Specialized for parts whose structure allows for simultaneous cutting with multiple tools, significantly reducing machining time and making them suitable for mass production.

Automatic and semi-automatic lathes

Features: High degree of automation, feed, clamping and cutting sequence of blanks are controlled by cams. Automatic lathes can fully automate the entire machining process; semi-automatic lathes require manual loading and unloading of parts, but the machining process is still automatic.

Uses: Mainly used in the automatic mass production of bar parts, greatly reducing the labor intensity of the operator.

2. Large and specialized lathes

vertical lathe

Features: Spindle vertical, equipped with a large diameter disk, the workpiece is placed horizontally on the disk, the tool moves vertically.

Purpose: Specialized for machining disc or wheel parts with large diameter but short length.

Floor lathe

Features: The structure is similar to that of an ordinary lathe, but the spindle box and bed are separate. Equipped with a large diameter spline disk, the spindle rotates horizontally.

Uses: Suitable for machining parts with large diameters but not long, such as large pulleys or wheels.

3. High-precision and highly automated lathes

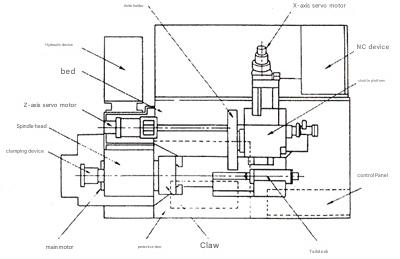

CNC Lathe

Features:High degree of automation: The entire machining process (including spindle speed change, tool feed, tool retraction, tool selection, etc.) is controlled by digital codes.

High flexibility: When the machining object is changed, it is only necessary to change the program (e.g. perforated paper or magnetic tape), without complex mechanical adjustments to the machine.

High precision: Computerized control enables high-precision machining with stable quality.

Uses and application scenarios:

- Complex parts processing: Suitable for processing complex shaped parts that are difficult to accomplish with ordinary lathes.

- Small batch, multi-species production: with the advantages of strong generality and quick changeover.

- High-demand parts: For parts with high precision requirements, large or valuable parts.

- Rapid Response Manufacturing: Capable of responding to parts that require frequent re-modeling or emergency production.