What is a Conventional Lathe Machine?

- Introduction

What is a Lathe Machine?

A lathe machine is one of the oldest and most fundamental tools in the world of machining. It is a machine tool that rotates a workpiece around an axis to perform various operations such as cutting, drilling, sanding, knurling, turning, and deformation. With the help of different cutting tools, material is removed from the workpiece to give it a desired shape and finish. Think of it as the mechanical version of a sculptor—carving precision shapes out of raw metal, wood, or plastic.

Importance of Lathe Machines in Manufacturing

The lathe is known as the “mother of all machine tools” because of its versatility. Without lathes, the manufacturing industry would struggle to produce precision components for vehicles, aircraft, medical devices, household appliances, and countless other products. It’s used to produce everything from bolts and nuts to complex parts for engines and turbines. From large industrial setups to small-scale workshops, lathes are indispensable for producing cylindrical parts with accuracy and speed.

The rise of CNC (Computer Numerical Control) machines has changed how machining is done, but the conventional lathe machine remains essential, especially for learning fundamentals, custom parts, and repair work.

- Understanding a Conventional Lathe Machine

Definition and Meaning

A conventional lathe machine is a manually operated machine tool used to perform turning operations. Unlike CNC lathes, which are automated and controlled by computer programs, conventional lathes require the operator to manually control the machine’s movement and the cutting process.

In simpler terms, if a CNC lathe is like a robot programmed to do a task, a conventional lathe is like a skilled artisan using their hands to shape a piece of material. It gives machinists full control over speed, feed, depth of cut, and tool positioning. That’s why many professionals still rely on it for prototyping, education, and precise manual work.

Brief History and Evolution

The concept of the lathe dates back thousands of years. The earliest versions were simple bow lathes, operated by hand. With the Industrial Revolution in the 18th and 19th centuries, powered lathes became more sophisticated. The conventional lathe as we know it today took form with advancements in mechanical engineering—bringing in precision lead screws, compound rests, and motorized operations.

These machines became the foundation for mass production techniques, especially in metalworking. Even with the emergence of digital machining, conventional lathes are still a crucial part of many workshops due to their reliability and versatility.

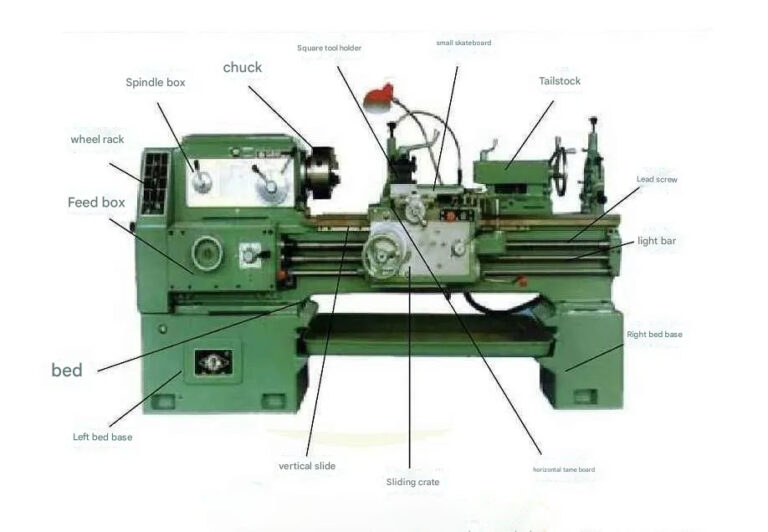

- Main Components of a Conventional Lathe

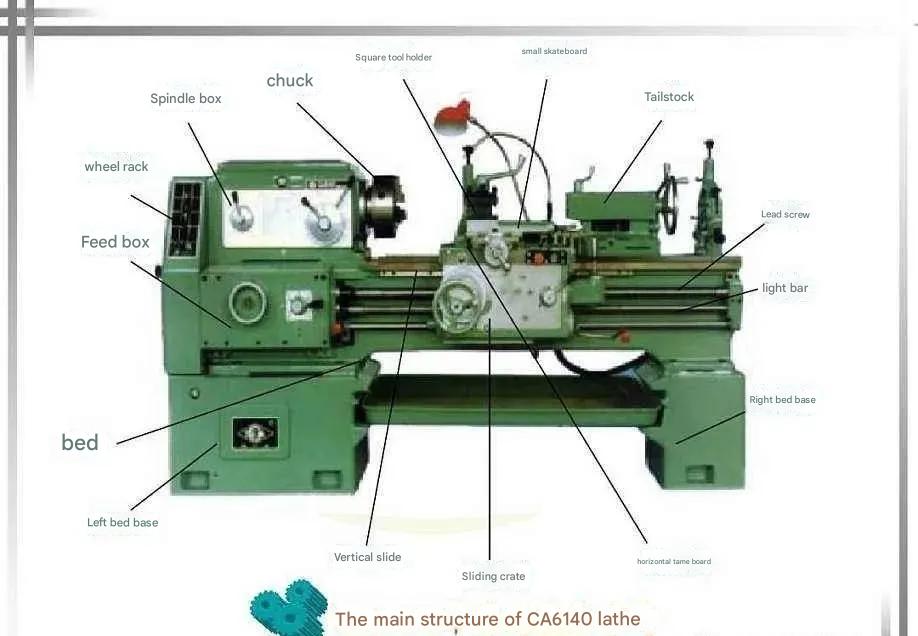

Understanding how a lathe functions starts with knowing its parts. Each component plays a vital role in the turning operation.

Bed

The bed is the main base of the lathe machine. It supports all other components and ensures alignment and stability during operation. Typically made from cast iron, it provides rigidity to absorb vibration during machining. On top of the bed are guideways that help the carriage and tailstock move accurately.

Headstock

The headstock is located on the left side of the lathe and houses the main spindle, speed change levers, and gears. It is responsible for holding and rotating the workpiece. Inside the headstock, the motor transmits power to the spindle using belts or gear systems. Some lathes allow multiple speed settings for greater flexibility depending on the material and operation.

Tailstock

Found on the opposite end of the headstock, the tailstock supports the free end of long workpieces. It also holds tools like drills or reamers for hole-making operations. The tailstock can slide along the bed and be clamped in place wherever support is needed.

Carriage

The carriage sits between the headstock and tailstock, and it holds and moves the cutting tool. It includes several sub-components:

- Saddle: Rides on the bed and supports the cross-slide.

- Cross-slide: Moves the tool left and right (perpendicular to the spindle).

- Compound rest: Allows angular positioning for taper cutting.

- Tool post: Secures the cutting tool in position.

Lead Screw and Feed Rod

These components enable automatic movement of the carriage. The lead screw is used for thread cutting, while the feed rod provides the power feed for general turning. This automation makes machining smoother and more consistent.

- Types of Conventional Lathes

There isn’t just one type of conventional lathe—different jobs require different machines. Here are the most commonly used ones:

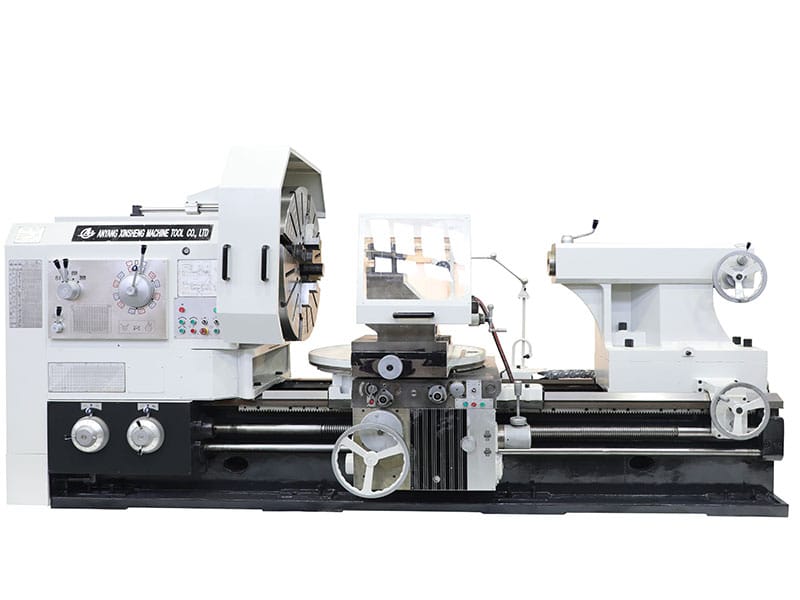

Engine Lathe

This is the most popular and versatile lathe, used in tool rooms and workshops. It supports various operations like facing, turning, tapering, threading, and more. It can handle medium to heavy-duty jobs.

Bench Lathe

Smaller in size and typically mounted on a workbench, these are ideal for light-duty operations. They are commonly used in training centers, watchmaking, and small component fabrication.

Speed Lathe

As the name implies, this type operates at high speeds. It has a simple design—just a headstock, tailstock, and tool rest. Ideal for woodturning, polishing, and spinning operations.

Toolroom Lathe

A more precise and high-quality version of the engine lathe, the toolroom lathe is used for fine, detailed work. It includes more accurate gear trains and accessories, allowing for superior finishes.

Gap Bed Lathe

This design features a removable section of the bed near the headstock, allowing larger diameter workpieces to be mounted. It’s perfect for irregular-shaped or oversized parts.

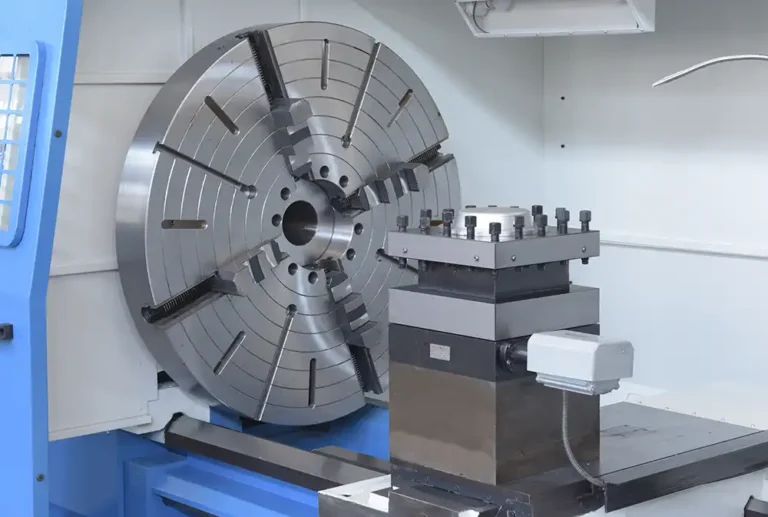

- Working Principle of a Conventional Lathe

The Basic Operation Process

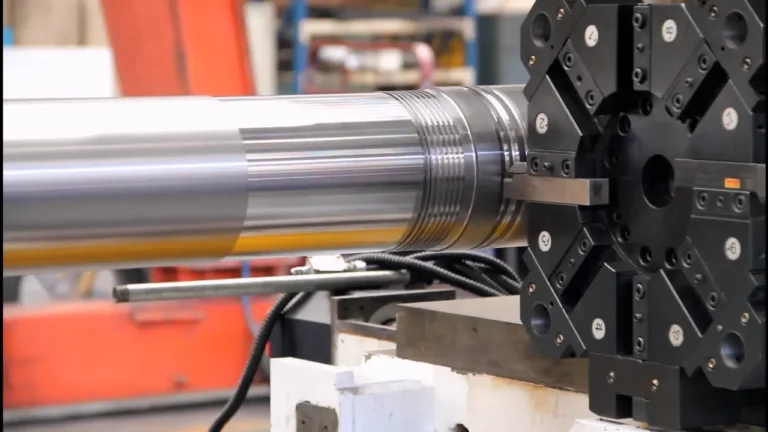

The conventional lathe operates on a simple principle: rotate the workpiece and move the cutting tool into it. The operator mounts the raw material (usually cylindrical) between the headstock and tailstock or in a chuck. The spindle rotates the material while the cutting tool—mounted on the carriage—is fed into the workpiece.

Depending on the operation, the tool can move longitudinally (parallel to the workpiece) or transversely (across the diameter). Material is shaved off in a controlled manner, resulting in smooth and precise dimensions.

Role of Rotating Workpiece and Stationary Tool

Unlike a milling machine, where the tool rotates, in a lathe, the workpiece spins. This setup is perfect for producing symmetric objects around an axis—think pipes, rods, bushings, or shafts. The cutting tool remains stationary (except for feed movement) and removes material gradually.

Speed, feed rate, depth of cut, and tool geometry are all factors that influence the final result. Operators need to skillfully adjust these parameters based on the type of material and desired finish.

- Common Operations Performed on a Conventional Lathe

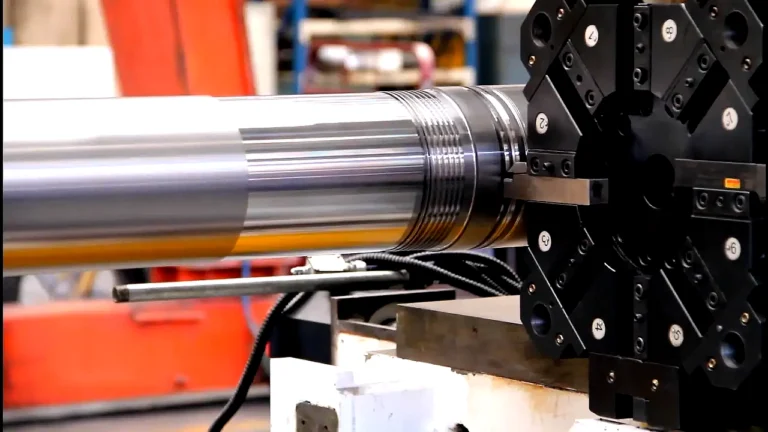

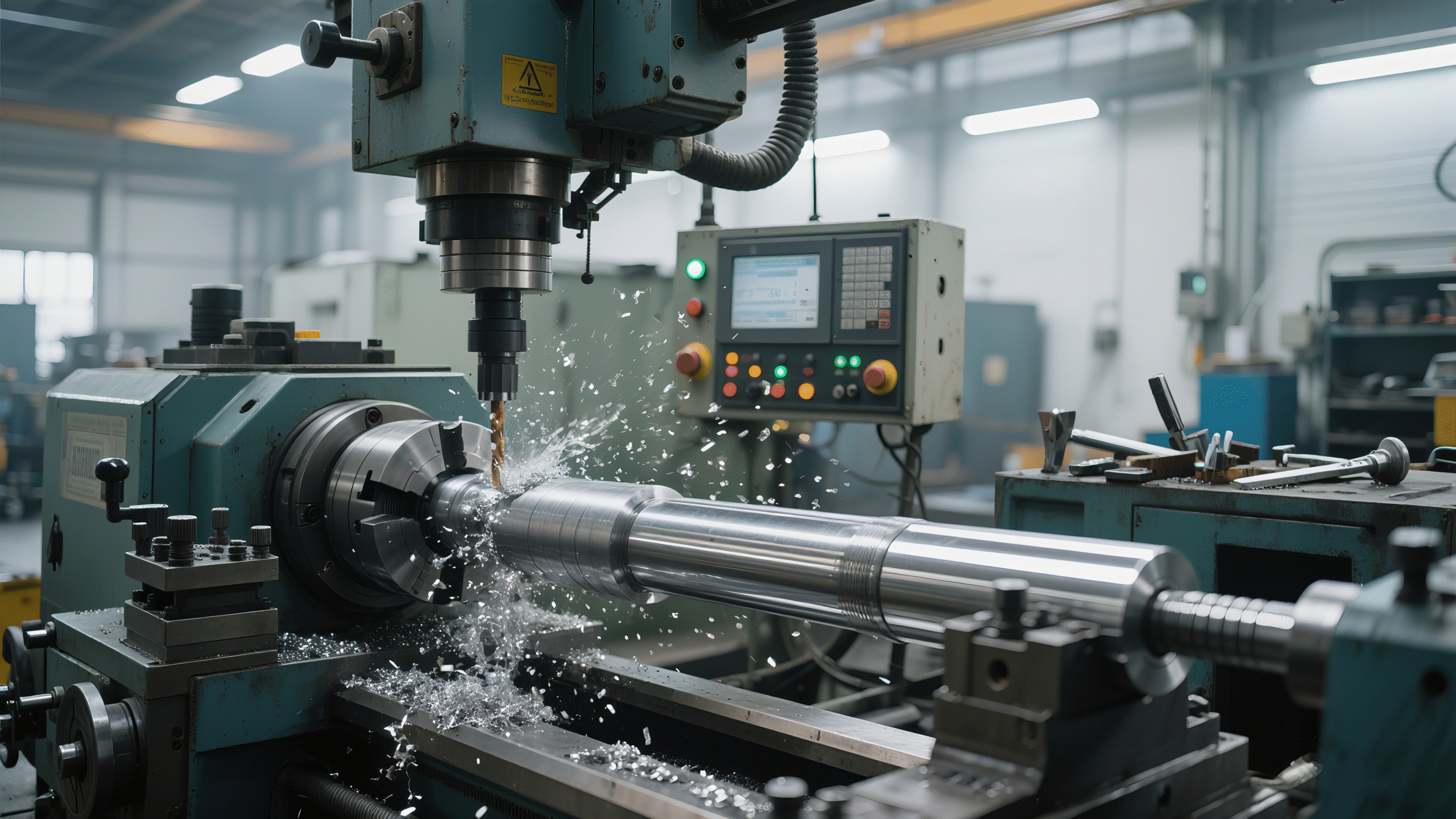

Turning

Turning is the most basic operation performed on a lathe. It involves removing material from the external surface of a rotating workpiece to reduce its diameter. The cutting tool moves parallel to the axis of rotation. It’s used to create cylindrical shapes, improve surface finish, or prepare the part for more precise operations.

There are several subtypes of turning:

- Rough turning: Removes large amounts of material quickly.

- Finish turning: Achieves precise dimensions and smoother finishes.

Facing

Facing involves cutting the end of the workpiece to produce a flat surface that’s perpendicular to its axis. The tool moves perpendicular to the spindle axis, usually from the outer edge inward. This is often the first operation to ensure the part has a clean, flat surface for accurate measurement.

Parting

Parting, also known as cutoff, is the process of slicing off a part from the main workpiece using a narrow cutting tool. It’s precise and quick, often used in high-volume production environments.

Thread Cutting

One of the standout features of a conventional lathe is thread cutting. By using the lead screw to synchronize the movement of the cutting tool with the rotating workpiece, threads can be precisely formed. Operators can cut internal or external threads depending on the setup and tool used.

Drilling and Boring

With a drill chuck mounted in the tailstock, holes can be drilled into the center of the rotating workpiece. Boring, on the other hand, enlarges existing holes with better precision. These operations expand the lathe’s versatility beyond turning.

Knurling

Knurling creates textured patterns on the surface of the workpiece, often for grip enhancement. It’s commonly found on tool handles, knobs, and fasteners.

- Materials Machined on a Conventional Lathe

Metals

Lathes can handle a wide variety of metals, from soft aluminum to hard stainless steel. The machinability of the metal determines the tool type, speed, and feed rate. Commonly machined metals include:

- Mild steel

- Aluminum

- Brass

- Stainless steel

- Cast iron

Plastics

Many industrial plastics like nylon, Delrin, and PVC can also be machined on lathes. They require sharp tools and careful speed control to prevent melting or deformation.

Wood

While not typical for metal lathes, conventional lathes can handle wood with the right tooling. Woodturning is a separate craft but shares the same basic principles.

Composites

Advanced shops might use lathes to shape composites like carbon fiber or fiberglass. These materials require special tools and safety precautions due to hazardous dust.

- Advantages of Using a Conventional Lathe

Versatility

Conventional lathes can perform multiple operations with minimal setup changes. Whether it’s turning, facing, drilling, or threading, one machine can handle it all. This makes them ideal for general-purpose shops and maintenance departments.

Affordability

Compared to CNC lathes, conventional models are significantly more affordable. This makes them accessible to hobbyists, small workshops, and educational institutions.

Manual Control

One of the biggest advantages is the level of control the operator has. You can feel the material, hear the tool engagement, and make real-time adjustments—something not possible with automated machines.

Skill Development

Using a conventional lathe helps operators build a strong foundation in machining. You learn feed rates, tool geometry, surface finish requirements, and how different materials respond to cutting.

- Limitations of Conventional Lathe Machines

Manual Labor

All operations must be controlled by the operator, which increases fatigue and reduces productivity compared to CNC systems. Human error can also affect the consistency of production.

Limited Automation

Without computerized controls, repeating the same task multiple times with identical precision is challenging. This makes conventional lathes less suitable for mass production.

Learning Curve

Although they’re great for skill development, conventional lathes require proper training. A novice operator might make costly mistakes if not supervised.

Safety Risks

Manual lathes expose the operator to rotating parts, sharp tools, and flying chips. Proper safety gear and training are essential to prevent injuries.

- Maintenance and Safety Tips for Conventional Lathes

Daily Maintenance

Keeping a lathe in top condition requires regular checks:

- Lubricate moving parts like the carriage and lead screw.

- Clean chips and debris from the bed and tool post.

- Inspect belts and gears for wear and tear.

- Check oil levels and coolant systems if equipped.

Safety Best Practices

- Always wear safety goggles and avoid loose clothing.

- Keep your hands away from the rotating chuck.

- Use guards and shields where available.

- Stop the machine before making any tool changes.

- Never leave the machine running unattended.

Operator Training

Training isn’t just about how to use the machine, but also how to read blueprints, calculate feed rates, and select the right tools. Refresher courses and regular assessments help maintain a high standard of work and safety.

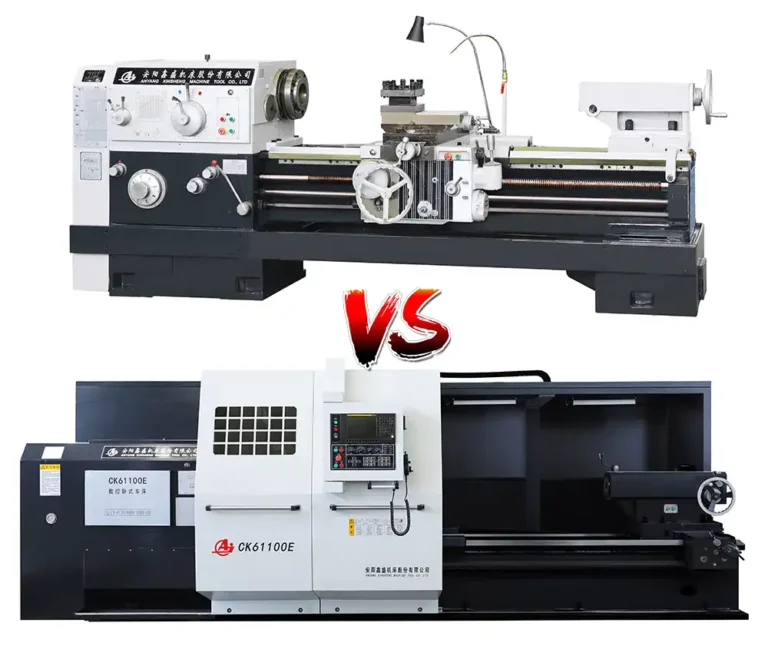

- Comparing Conventional Lathe with CNC Lathe

Operational Differences

Conventional and CNC lathes operate on the same principle—rotating the workpiece against a cutting tool—but they differ significantly in execution. A conventional lathe relies on the machinist’s hands to guide the cutting tool, adjust feed rates, and monitor the operation in real-time. In contrast, a CNC (Computer Numerical Control) lathe uses pre-programmed software to automate these movements with extreme accuracy.

While the conventional lathe gives the operator full manual control and tactile feedback, the CNC lathe excels in repetitive tasks, ensuring uniformity across hundreds or thousands of parts.

Precision and Efficiency

CNC lathes can produce complex parts with high precision, repeatability, and minimal error. Conventional lathes, though capable of fine accuracy, require a skilled machinist to achieve similar results, which is more time-consuming. However, for one-off jobs or repair work, a conventional lathe may be faster due to the lack of programming requirements.

Cost Factor

Conventional lathes are significantly cheaper than CNC machines, both in purchase and maintenance. This makes them a more practical choice for small shops or educational settings. CNC machines, while more expensive, offer better ROI in high-volume production settings.

Learning and Skill Requirements

Using a conventional lathe demands more hands-on skill. It’s ideal for those learning the fundamentals of machining. A CNC lathe, on the other hand, requires programming knowledge (e.g., G-code) and an understanding of digital systems, though less manual dexterity.

- Industries That Use Conventional Lathes

Automotive

In the automotive industry, conventional lathes are used for making and repairing parts like axles, shafts, pulleys, and bushings. They’re often found in maintenance workshops for small-batch or emergency repairs.

Aerospace

Precision and quality are vital in aerospace. While CNC is dominant, conventional lathes still play a role in custom tooling, prototyping, and maintenance tasks.

Metalworking and Fabrication

From small workshops to large metal fabrication units, lathes are essential for turning raw metal into usable parts. Conventional lathes are perfect for custom jobs, low-volume production, or jobs requiring manual fine-tuning.

Education and Training

Most technical colleges and trade schools teach machining basics on conventional lathes before moving to CNC. It helps students understand the principles of metal cutting, material behavior, and machine operations.

Maintenance and Repair Workshops

Many plants and facilities keep a conventional lathe in their maintenance department to quickly repair or fabricate a broken component without outsourcing or waiting for delivery.

- How to Choose the Right Conventional Lathe

Determine Your Needs

First, identify what kind of work you’ll be doing:

- Light-duty tasks: Consider a bench lathe.

- Medium to heavy-duty turning: Go for an engine or gap bed lathe.

- Precision work: A toolroom lathe is best.

Size of the Workpiece

Check the swing over bed (the maximum diameter the lathe can turn) and distance between centers (the maximum length of the workpiece). Choose a lathe that can comfortably handle your expected dimensions.

Tooling and Attachments

Make sure the lathe supports standard tooling sizes and comes with essential attachments like:

- 3-jaw and 4-jaw chucks

- Faceplates

- Steady and follow rests

- Toolposts and holders

Build Quality and Brand Reputation

Look for brands known for durability and accuracy. The frame should be solid, preferably cast iron. Avoid lightweight or low-quality imports unless they come highly recommended.

Support and Maintenance

Ensure spare parts, manuals, and technical support are readily available. Machines with complex gear trains or electronic components need reliable after-sales service.

- Tips for Improving Efficiency on a Conventional Lathe

Tool Selection

Use the correct tool material and geometry based on your workpiece:

- High-speed steel (HSS) for general use

- Carbide for harder materials and higher speeds

Proper Setup

Ensure your workpiece is securely clamped and properly centered. Misalignment can cause uneven cuts, tool chatter, and accidents.

Optimize Cutting Parameters

Adjust speed, feed, and depth of cut based on:

- Material hardness

- Desired surface finish

- Tool life

Coolant and Lubrication

Use appropriate coolants to reduce heat and increase tool life. For some materials, dry machining works best, but others require plenty of lubrication to avoid tool wear.

Routine Checks

Inspect tools and alignment before each job. Even small misalignments can ruin the part and damage the machine.

- The Future of Conventional Lathes

Still Relevant in a Digital Age

Despite the rise of automation and smart factories, conventional lathes continue to hold value. They’re reliable, affordable, and perfect for certain applications like repair work, prototyping, and training.

Integration with Modern Technology

Some conventional machines are now fitted with digital readouts (DROs), enhancing precision without full automation. Others include variable speed drives and motor upgrades for better performance.

Sustainability and Repair Culture

With the growing focus on sustainability, more industries are looking to repair and reuse rather than replace. Conventional lathes are ideal for custom repair parts and refurbishing worn components.

Conclusion

A conventional lathe machine is a cornerstone of machining that continues to earn its place in workshops and industries worldwide. Its simplicity, reliability, and versatility make it a must-have for anyone serious about manufacturing or metalworking. Whether you’re a seasoned machinist or a student just getting started, mastering the conventional lathe opens up endless possibilities in the world of precision engineering.

FAQs

- What materials can be machined on a conventional lathe?

Conventional lathes can machine metals (steel, aluminum, brass), plastics (nylon, PVC), and even wood, depending on the tooling used. - How is a conventional lathe different from a CNC lathe?

A conventional lathe is manually operated, giving the user full control. CNC lathes are automated and ideal for high-precision, repeatable work. - Is a conventional lathe suitable for beginners?

Yes! It’s often recommended for beginners because it helps them learn the fundamentals of machining and tool control. - What are some common operations done on a lathe?

Turning, facing, threading, parting, boring, and knurling are the most common operations. - Can I cut threads with a conventional lathe?

Absolutely. Thread cutting is one of the main functions of a conventional lathe, using the lead screw for synchronized tool movement.