Will Manual Lathes Be Phased Out? Why They Remain Indispensable in Mechanical Processing

With the widespread adoption of CNC machines, many might wonder: will manual lathes (also known as conventional lathes) eventually be phased out? The answer is: as long as mechanical processing exists, manual lathes will never be completely eliminated. While CNC machines offer significant advantages in automation and efficiency, manual lathes, with their unique applications and cost-effectiveness, continue to play an indispensable role in modern mechanical processing.

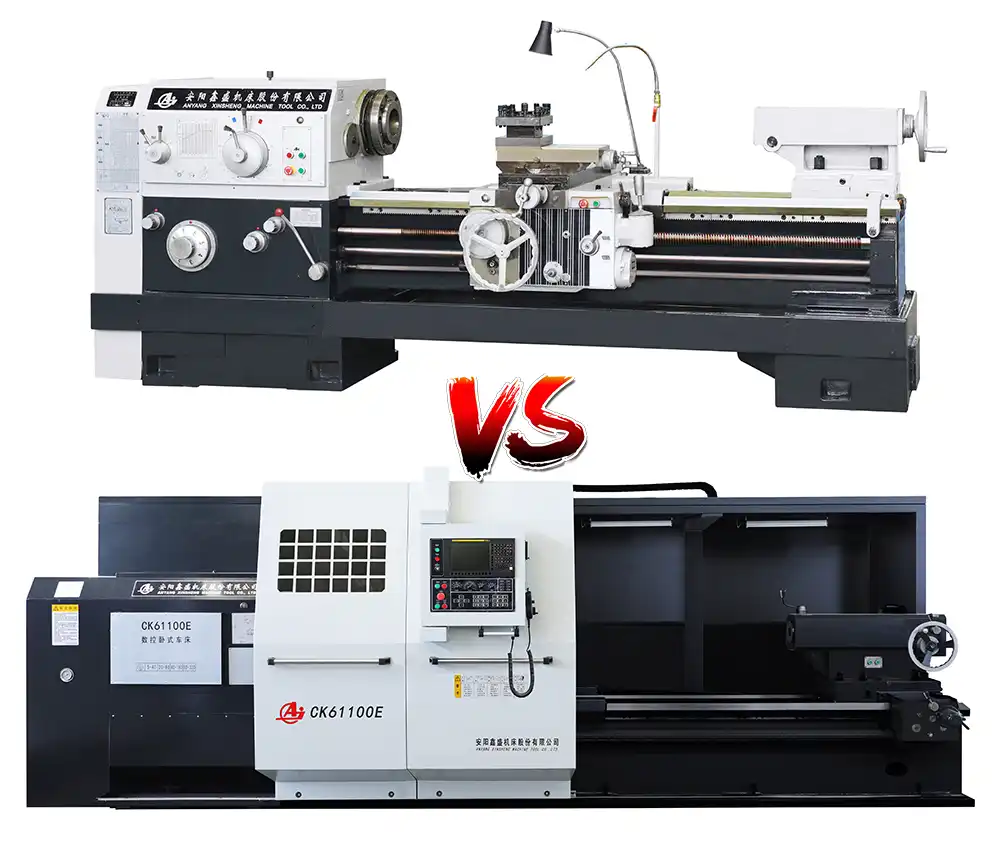

Manual vs. CNC Lathes: Power Debate and Structural Differences

First, let’s clarify a common misconception: the main spindle drive motor of a manual lathe is not more powerful than that of a CNC machine. In fact, modern CNC machines often have higher spindle motor power to support high-speed, high-precision cutting.

Characteristics of Manual Lathes:

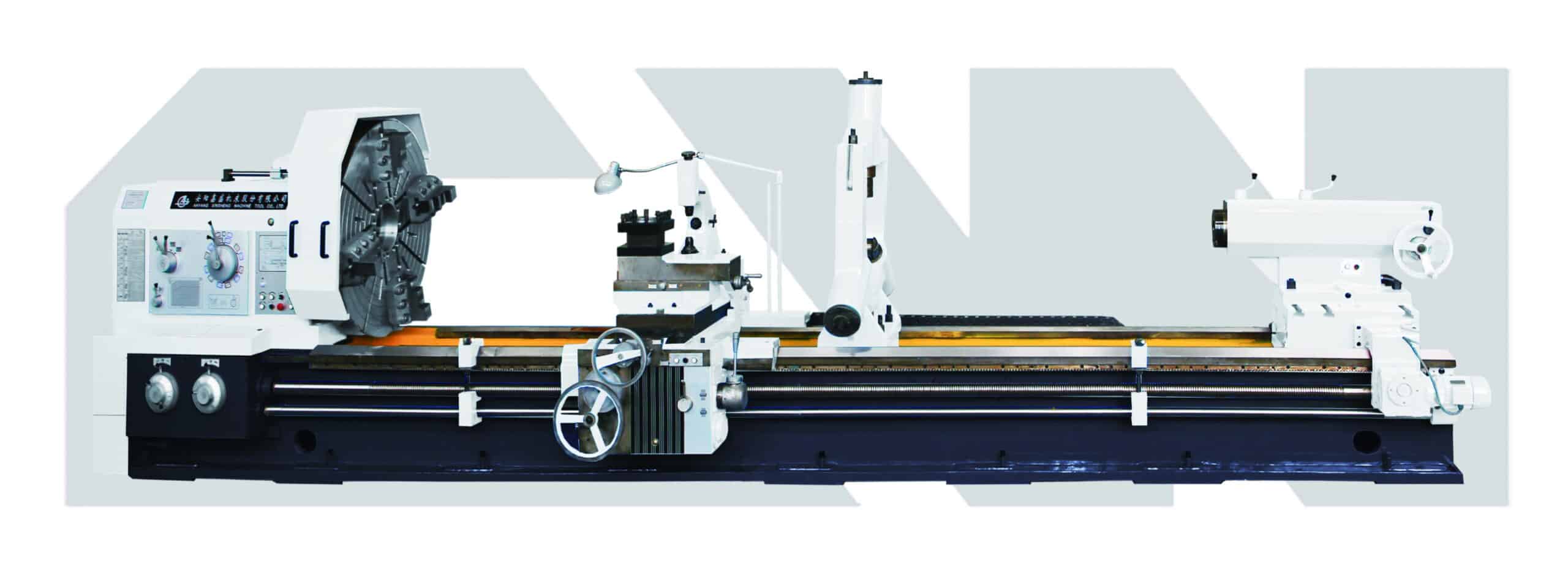

- Versatile: Manual lathes are a broad category, including instrument lathes, toolroom lathes, woodworking lathes, horizontal engine lathes, and vertical turret lathes, among others. They are general-purpose mechanical processing equipment, and a single manual lathe can handle most part processing tasks for a small workshop, factory, or repair shop.

- Transmission Method: The main spindle motor of a manual lathe transmits power via belts and through a gear train in the headstock to the lead screw, enabling automatic feed for turning. This means one motor drives all the machine’s movements.

- Cost-Effective: A decent 6140 manual lathe costs around three to four thousand US dollars, significantly less than the seven to eight thousand dollars or more for a CNC machine, offering an advantage in initial investment.

Characteristics of CNC Machines:

- Independent Drives: On a CNC machine, the main spindle motor only drives the spindle, while the X-axis, Y-axis (and often the Z-axis), and tool turret are driven by independent servo motors, allowing for precise control and multi-axis coordination.

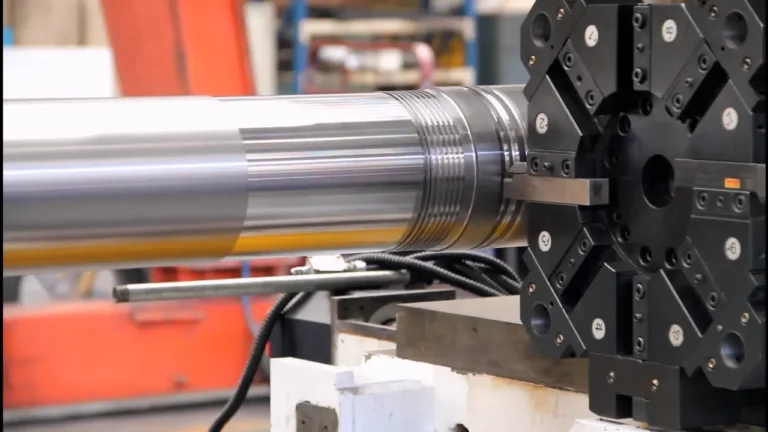

- High Integration: Modern CNC machines often use direct drive for the main spindle and spindle transmission, and some even feature integrated spindles where the motor, spindle, and support system are combined into one unit for higher precision and rigidity.

Unique Advantages of Manual Lathes in Practical Machining

While CNC machines are more efficient for mass production, manual lathes offer irreplaceable advantages in many specific scenarios:

- Quick Trimming and Emergency Machining: When a part’s inner bore is slightly out of tolerance and requires simple trimming, putting it on a manual lathe for a “one-cut” adjustment is far more efficient than the complex programming and tool setting required on a CNC machine. Manual lathes are intuitive and convenient, allowing for quick responses to such temporary, non-batch processing needs.

- Simple Operations: For basic operations like chamfering or drilling, a manual lathe can easily complete the task without the need for complex CNC programming, saving time and labor costs.

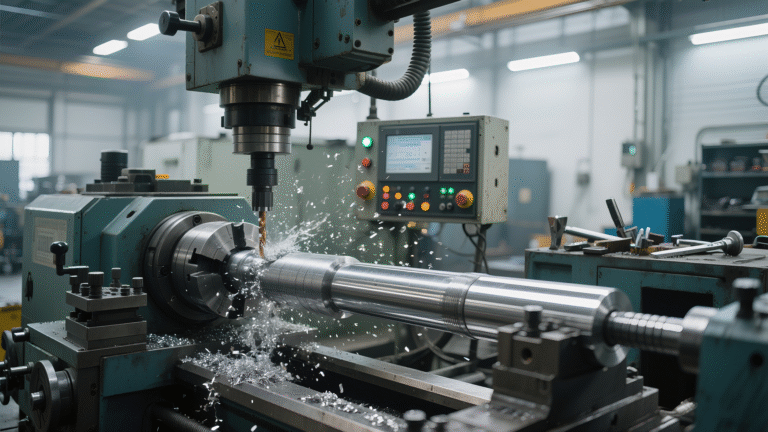

- Roughing Load Sharing: During roughing, although the feed rate is slow, the depth of cut is significant. Assigning roughing tasks to a manual lathe can effectively reduce the workload on CNC machines, protect them, and extend their service life, leading to substantial economic benefits. With automatic feed, a manual lathe can slowly remove most of the material, preparing the part for subsequent finishing.

- Essential in Tool Rooms: In modern mechanical processing factories, tool rooms or tool shops are indispensable, as they are responsible for producing the specialized tools, fixtures, clamps, and measuring instruments needed for machining. Manual lathes are crucial equipment in these tool rooms, and many of these specialized tools still rely on manual lathes and the skillful craftsmanship of experienced machinists.

The Advantages of Manual Machines Are Even More Apparent in Milling

The advantages of manual machines are not limited to lathes; they are also prominent in milling. For example, when a simple anti-rotation slot needs to be milled, a turret mill can quickly get the job done. If a machining center were used instead, it would involve a series of more complex steps like drawing, programming, and tool setting, which would be less efficient and more time-consuming, especially for less experienced operators.

How to Choose the Right Machine for Your Needs?

Ultimately, the decision of whether to use a manual lathe, a CNC machine, or a combination of both must be based on your specific requirements.

- If your business primarily involves high-volume, high-precision, and complex part processing, then investing in CNC machines is a wise choice.

- If you need to handle numerous small-batch, diversified, urgent, or simple trimming tasks, or if you require flexible machining capabilities in a tool room, then a manual lathe will be an indispensable partner.

- For startups or individuals with limited budgets, an affordable manual lathe can quickly help you establish basic machining capabilities.

Manual lathes and CNC machines are not in a relationship of mutual replacement, but rather complementary coexistence. In the future, they will continue to play their respective roles in their specialized fields, jointly driving the development of the mechanical processing industry.